A new nanotechnology covering for polycarbonate greenhouses is about to give a boost to growers everywhere, as its special nanostructured content has been proven to aid photosynthesis, increasing yields of vegetables and flowers, as well as accelerating fruit ripening.

Polycarbonate coverings have long been used in the manufacture of industrial and horticultural greenhouses. They are much cheaper and safer than glass structures, as well as being easier to construct and maintain, but until recently, the technology has remained fairly static. A simple plastic roof kept the worst of the cold and wind away from the plants, while also allowing the temperature to build up earlier in the season; boosting seed germination and crop growth.

But now, a special nanostructured additive is being used to increase this greenhouse advantage even further. By helping to control the light frequency that reaches the plants the nanocoating is boosting photosynthesis.

Developed in Russia in 2012 at the research and production department of PLASTILUX-GROUP LLC with the assistance of scientists from the Institute of Plant Production and Belgorod State Agricultural Academy, the coating has now been added into a range of industrial and domestic greenhouses which are increasing farm yields by as much as 48%.

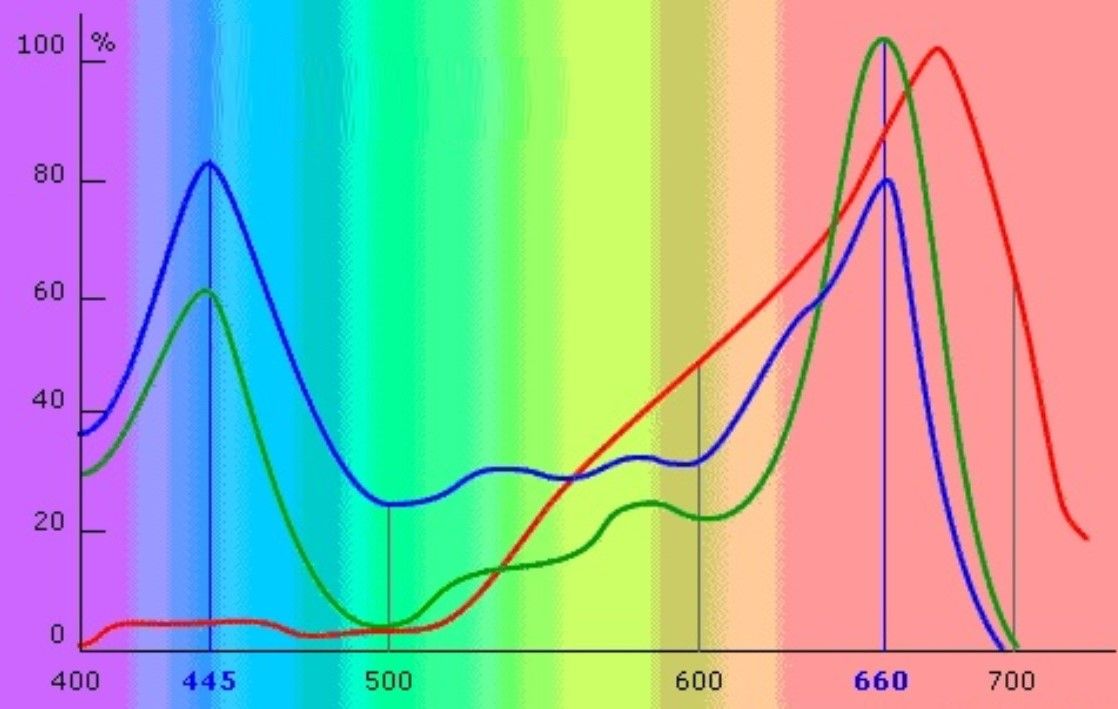

The technology is based on the effect of 660 nm light radiation to which plants are especially responsive. The conversion of harmful UV rays into a spectrum of light radiation that is useful to plants, coupled with the natural warming inside the greenhouse, can accelerate plant development by as much as 3 or 4 weeks.

As the company’s website explains, “Phytochrome is a red light receptor that is responsible for the growth and fruiting of flora, and is an energy supplier for photosynthesis. When agricultural crops are exposed to red light with a wavelength of λ = 660 nm, the process of converting the phytochrome of an inactive form into an active one starts, as does enhanced synthesis of chlorophyll and carotenoids. Thanks to the photoconversion of active chromoproteins, the most intensive growth and good fruiting of vegetable crops is achieved. This principle of photoconversion underlies the efficiency of using GREENHOUSE-nano polycarbonate.”

Already the feedback from customers using the trademark polycarbonate growing system, called GREENHOUSE-nano, is exceeding expectations. With the company reporting how a client had been able to grow 30% more tomatoes and cucumbers in her new pink polycarbonate greenhouse, than she was able to yield from her adjacent standard polycarbonate greenhouse, despite the standard greenhouse using special phytolamps.

Another customer grew peanuts, arugula, and basil in a greenhouse made of the GREENHOUSE-nano polycarbonate, which he had never been able to cultivate under film cover before. While a Kiev businessman who cultivates large-flowering Grandiflora petunias for a living, was able to sell his product a month before his competitors, increasing his nursery profit by 40%.

But alongside the anecdotal advantages of the nanostructured coating, the technology has been scientifically proven to increase crop yields. As the journal Belgrade Agriculture reports (pdf), studies have shown that, “… the impact of the use of a particular brand of cellular polycarbonate [namely] ‘GREENHOUSE-nano’ on the yield of cucumbers of new hybrids F1 Cadet and F1 Raisa, suitable for planting in the early spring, showed that they are best adapted for polycarbonate greenhouses ‘GREENHOUSE-nano’ in the winter-spring turn and demonstrate a significant increase in yield. The use of this polycarbonate [with nanostructured coating] in the construction of greenhouses increases yield of cucumbers by 39.9-47.8%.”

The new polycarbonate is durable enough to allow for an extended 10-year warranty, and also offers an ‘anti-fog’ coating which uses is hydrophilic properties to prevent the formation of large amounts of condensation, improving light transmittance and limiting fouling.

Nanomaterials are already influencing modern life in many ways. Today they are widely used in; plastics and other composites, military hardware, medical equipment, pharmaceuticals, cosmetics, paints, inks, rubber products such as car tyres, household electrical goods, high-end electric items such as satellites, crop protection products, fabrics and textiles, and sports equipment.

However, the breakthrough announcement that nanomaterials can now be employed to aid plant growth has taken nanotechnology to new ground.

The simple development of a nanocoating employed on a polycarbonate greenhouse to create a light-converting material that increases crop yields by 150% and reduces the ripening time for fruit and vegetables by almost a month may send shockwaves through the agricultural industry.

Photo credit: Polikarbonates