A team of chemists have used silver nanoparticles to create solid surfaces that can dynamically change colour if you touch or breathe on them. By incorporating invisible patterns in the nanoparticle films, consumers could ensure that products such as cigarettes, laptops, phones, or even high-end alcoholic drinks are genuine. This places nanoparticle technology on the front line of the fight against counterfeiting.

An Oct 2019 report by the European Commission found that 27 million articles imported into the EU infringed on intellectual property rights (IPR) were detained in 2018 with a street value of nearly €740 million. The most likely ‘fake’ items cigarettes (15%), toys (14%), packaging material (9%), labels, tags and stickers (9%) and clothing (8%). While home body care articles, medicines, and electrical household goods accounted for the majority of the remainder.

The total value of illicit products that are actually sold on the market is unknown.

It has long been known that nanoparticles have special colour emitting properties; giving them unique abilities over standard dyes and raw materials for paint. Even during medieval times, chemists used gold nanoparticles to stain glass red for church windows.

Today, commercial pigments are known to either absorb or scatter (reflect) different wavelengths of light. If a manufacturer wishes to change the colour, he must change the chemical formula of the product. This is both expensive and time consuming, often requiring the new design of a molecule for each new colour. Additionally, pigments usually either absorb or scatter light; rarely both.

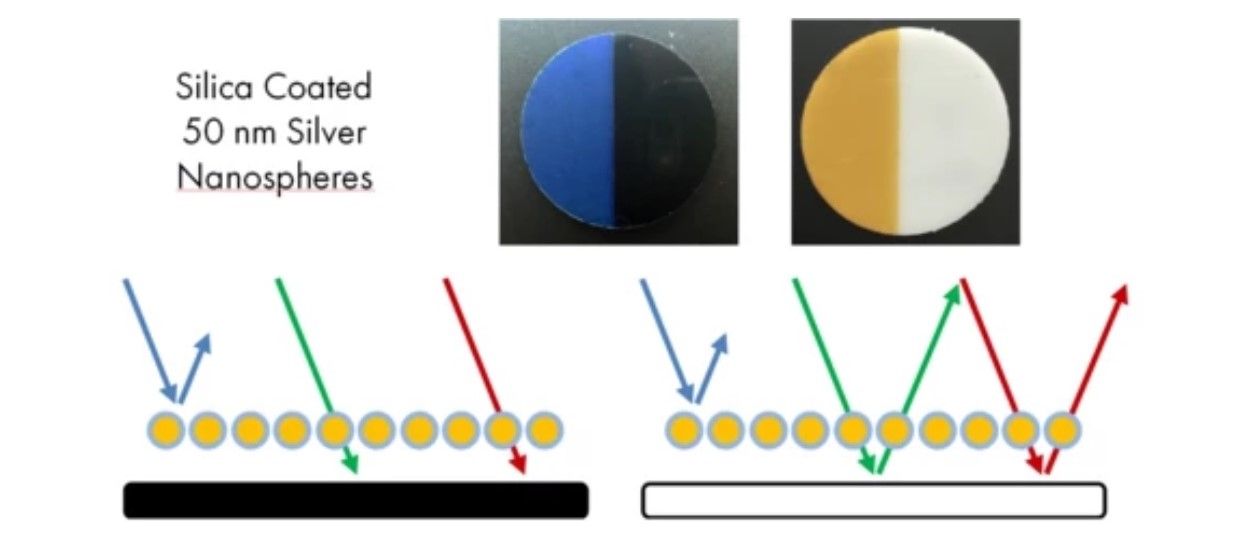

However, nanoparticles are far more versatile, as the journal Nano Composix explains, “Nanoparticles, can be engineered to absorb, scatter, or both absorb and scatter. Since the particle colours depend upon size and shape, very subtle changes can be made without requiring a new formulation to be developed. If only very small changes in colour are required, for example, the dimension of the nanoparticles can be increased or decreased by just a few nanometres. This level of synthetic control provides an unprecedented level of tunability which cannot be achieved using standard dye and pigment technology.”

This tunability and reversibility has great potential, but up until recently it was only possible in liquids, dramatically limiting its practical uses.

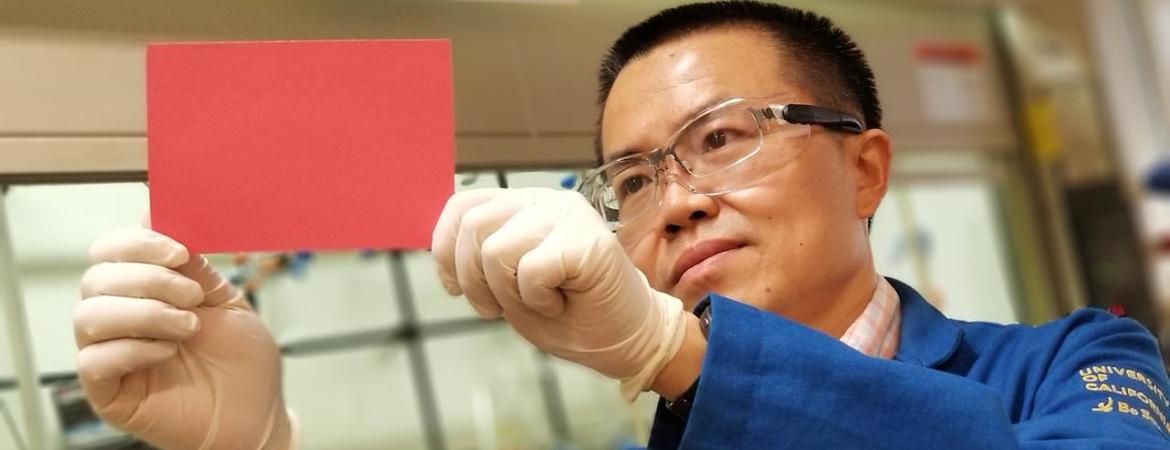

But now a team from the University of California, Riverside has fabricated a ‘plasmonic’ colour-switchable film made from silver nanoparticles (AgNPs), a breakthrough with potential in numerous industry sectors.

As Prof. Yadong Yin, who led the study, outlines, “Rapid and reversible tuning of plasmonic colour in solid films, a challenge until now, holds great promise for a number of applications. Our new work brings plasmonic metal nanoparticles to the forefront of colour-converting applications.”

The nanotechnology advance was made by coating glass with a layer of sodium borate, or borax, onto which was then sprayed a minute film of AgNPs. As each AgNP has ‘capping ligands on its surface’ (creating a distance between the nanoparticles) they do not clump together.

The understanding of how nanoparticles interact with each other was key to the breakthrough.

As the university press release explains, “In the presence of water or moisture, borax turns to boric acid and releases hydroxyl ions. These ions ‘deprotonate’ a chemical group of the ligands, resulting in the loss of a proton and the addition of a negative charge on the AgNPs. Repulsion forces push the negatively charged nanoparticles away from each other.”

At rest, the nanoparticles are pink, but as the distance between them changes they begin reflecting a different colour; yellow.

Furthermore, the colour changing is completely reversible. As the journal states, “When the moisture is removed, the boric acid converts back to borax by capturing hydroxyl ions, initiating a protonation of the ligand's chemical group. This causes a reduction in surface charges on the ligand, weakening the repulsion forces between the AgNPs and causing them to draw closer to each other and aggregate. With interparticle distances now reduced, the colour of the AgNP film switches back from yellow to pink, demonstrating full reversibility.”

Removing or adding water from the nanoparticle film causes plasmonic colour-switching which can even be activated by just the humidity around human fingers, which can be as high as 100%.

As Yin highlights, “In our experiments, we exposed the AgNP film to moisture of 80% relative humidity and found the film changed colours from pink to red, orange, and finally yellow.”

This means that the film doesn’t even need to be touched to react but must only be in close proximity to human skin or breath.

Significantly, the moisture-responsive AgNP films are completely reversible and repeatable, with tests showing continued colour changing after more than 1,000 cycles.

The study has now been published in the scientific journal Angewandte Chemie, where the researchers state, “The fast and reversible switching of plasmonic colour … by exposure to trace amounts of water vapor … holds great promise for many applications.”

One such practical option is for fast and stable brand verification. As Yin explains, “Various high-resolution patterns can be effectively encrypted in the AgNP films through a lithography process and then decrypted when exposed to moisture in human breath or from fingertips. This allows for a convenient, rapid, and touchless method that can be used in information encryption and product authentication.”

Adding that, “Other foreseeable applications include secure communication and calorimetric real-time environment or health monitoring.”

Many industry sectors have long sought fast, stable, and reversible colour switching. Now that it’s here, let’s see where entrepreneurship takes it.

Photo credit: UCR, Gotireland, Englishrepublika, Phys.org, & Sonnyholmes.