Researchers have found a way to produce nanowires which are only 3 atoms wide and yet are 50 times longer than standard nanowires. Furthermore, the wires can be isolated to protect their special properties as “atomically quasi ‘1D’ objects”. The researchers also found that single nanowires twist when perturbed or stimulated, making them possible candidates for switches in nano-electronical devices of the future.

For a long time now, researchers have been exploring the potential of two-dimensional materials, whose exceptional electrical and thermal conductivity as well as their mechanical strength and optical properties have opened up a world of possibilities in material science. The most famous of these materials, graphene, has already been utilized in the production of high-spec batteries, biosensors, and even artificial tissue.

More recently, researchers were able to successfully isolate individual layers from 2D van der Waals-layered materials, which further opened frontiers towards harnessing graphene’s electrical properties. However, capturing individual 1D objects has proven to be a much greater challenge.

Now a team from Tokyo Metropolitan University have made a key breakthrough by using carbon nanotubes as a template for the production of nanowires of transition metal monochalcogenide (TMM).

TMMs are a class of material that nanotechnology scientists have theoretically known about for more than 30 years. Recently, they have received greater attention as potential nanowires for use in precision nanoelectronics.

Earlier studies were only able to make small quantities of nanowire, which were typically of poor quality. As the online journal Science Daily explains, “… these [nanowires] were usually bundled, too short, mixed with bulk material or simply low yield, particularly when precision techniques were involved e.g. lithography. The bundling was particularly problematic; forces known as van der Waals forces would force the wires to aggregate, effectively masking all the unique properties of 1D wires that one might want to access and apply.”

By using carbon nanotubes as a structure, Assistant Professor Yusuke Nakanishi and his team can produce bulk quantities of well-isolated single nanowires of TMM.

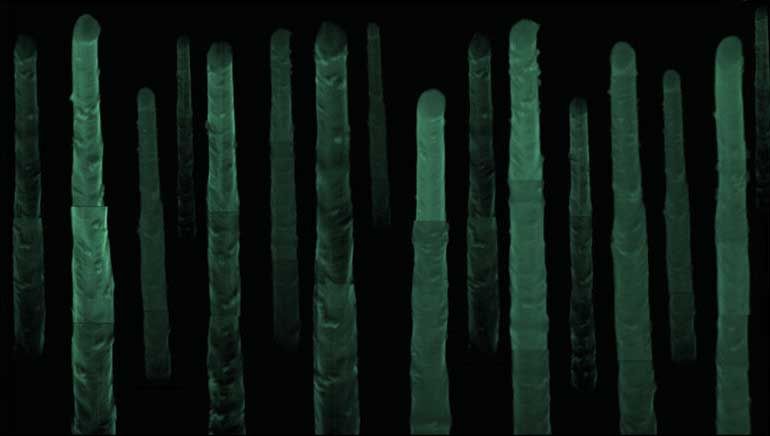

The nanowire production process was described as follows by the scientific journal EurekAlert; “They used tiny, open-ended rolls of single-layered carbon, or carbon nanotubes (CNTs), to template the assembly and reaction of molybdenum and tellurium into wires from a vapor. They succeeded in producing single isolated wires of TMM, which were only 3-atoms thick and fifty times longer than those made using existing methods. These nanometer-sized CNT ‘test tubes’ were also shown to be not chemically bound to the wires, effectively preserving the properties expected from isolated TMM wires. Importantly, they effectively ‘protected’ the wires from each other, allowing for unprecedented access to how these 1D objects behave in isolation.”

The team have now published their results in the journal NanoLetters, where they explain how they, “… report the facile synthesis of isolated transition-metal monochalcogenide MoTe nanowires by using carbon nanotubes (CNTs) as molds. Individual nanowires are perfectly separated by CNTs with a minimal interaction, enabling detailed characterization of the single wires.”

Further experiments on these isolated wires found that they reacted unexpectedly under stimulation.

When the team exposed the nanowires to an electron beam they ‘exhibited a unique twisting effect’. Such behaviour, witnessed via transmission electron microscopy (TEM), had never been seen before, and is thought to be unique to isolated wires.

While the full reasoning behind the nanowires’ reaction to electrons is not fully understood, the way that a straight wire is able to bend and twist may offer a potential use as a nanoscale switch which could be applied to microscopic circuitry.

The team is now continuing their research on the twistable nanowires with a hope to further expanding the variety of applications. Already nanowires can be used in the manufacture of biosensors, solar panels, flexible capacitors, as oil absorbing mats, in water filtration devices, chemical vapor sensors, and transistors

As the study reports, “The ability to make well-isolated 1D nanowires might significantly expand our understanding of the properties and mechanisms behind the function of 1D substances.”

Understanding the nanotechnology and production of 1D materials could well change everything.

Photo credit: NanoLetters, Inredox, and Phys.org