Having already answered some key questions on carbon nanotubes or CNTs (what are they?, how do they help plant growth?, are they toxic?) in part one of this blog, it is necessary to move onto other crucial questions.

What are the benefits of CNTs as a fertilizer feedstock?

Numerous plant species have been scientifically shown to benefit from using carbon nanotubes as a fertilizer raw material.

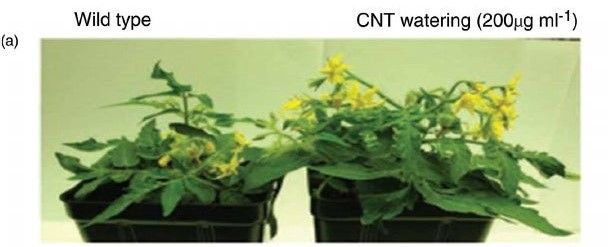

For example, a study by an international team, partially based at the University of Arkansas, found that, “Tomato plants grown in soil supplemented with CNTs produce two times more flowers and fruit compared to plants grown in control soil.”

While a similar study noted that adding multi-walled carbon nanotubes (MWCNTs) once per week to tobacco plants daily watering resulted in an approximate, “… 55 - 64% enhancement in the fresh biomass and overall growth of tobacco cells.” When the same test was carried out on tomato plants, “… there was an increase in plant height, number of leaves/flowers/fruits, and overall size of fruits.”

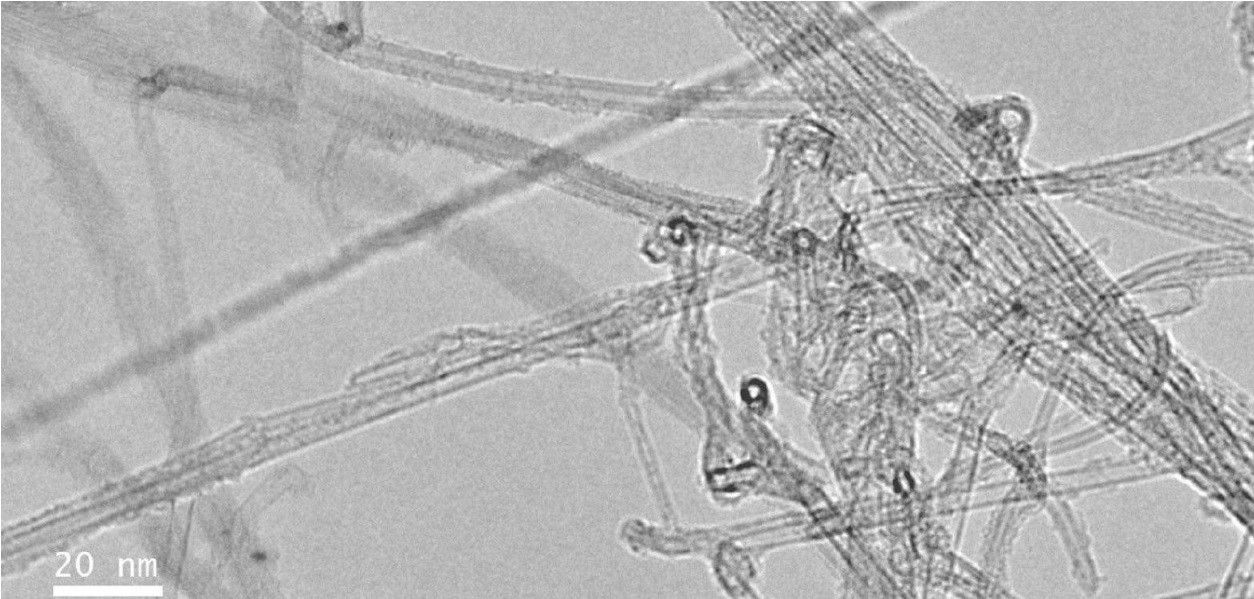

Specifically, the benefits of nanoscale carbon was pinpointed to be in nanotube form in a 2011 study which looked at various carbon nanoproducts and their impact on plants. The study compared, “… the effect of differently shaped nanocarbons, using four different nanocarbons, namely; activated carbon (AC), few-layered graphene, MWCNTs, and single-walled carbon nanotubes (SWCNTs) using the same concentration (50μ gml-1).”

The results observed that, “The maximum change in plant physiology was noticed only with the plants exposed to SWCNTs and MWCNTs and was maximum in the case of MWCNTs. In the roots and leaves of MWCNT-treated plants, they observed upregulation of the genes related to stress and water channel protein.”

Fullerenes (a ball-shaped nano-sized structure) have found only limited use as a fertilizer.

A 2017 study from the Chinese Academy of Sciences in Wuhan, also found that wheat plants could be grown with higher yields due to an improved defence against root fungi when supplied with MWCNTs as a fertilizer.

Carbon nanotubes and the question of purity

Alongside agriculture, carbon nanotubes have uses in many other industries. Pharmaceuticals, chemicals, polymers, textiles, electronics, transportation, energy, cosmetics, and construction all use CNTs.

However, what is important in every situation is the purity of the carbon nanotubes product.

An unavoidable aspect of the synthesizing process is the presence of metal impurities that slow down or prevent the abilities of the carbon nanotubes. While quality tubes generally have a 90% or more carbon content, cheaper CNT products can be bought containing as little as 50%.

Many high-spec applications, such as in military hardware, electronics, pharmaceutical products, and in the manufacture of satellites may require purity levels as high as 99.99%.

While this level of quality has not been required in any of the fertilizer studies to date, research has shown that purity is still a factor.

As a report published in the scientific journal Academia states, “Further control of the purity of nanocarbons manufactured using catalysts is an issue of concern for biological applications. Traces of metal present in such nanoderivatives synthesized using a metalcatalyst may cause adverse effects, so such events need to be clearly investigated.”

Exactly why CNTs should aid so many plant species is not entirely known, however there is no evidence to suggest that such a fertilizer raw material is detrimental to human health, as ultimately the active ingredient is simple carbon.

Further work is required to discover more about how crop yields can be improved with CNT fertilizers. As such, it is not yet possible to accurately predict how much of an impact this novel raw material will have on industrial agriculture.

Maybe, the effects will be too minimal to stop farmers’ addiction to traditional bulk fertilizer ingredients, such as nitrogen and phosphates. However, given the huge environmental cost of the agrichemicals industry, even a small uptake in CNT use in fertilizers could make a difference.

So, perhaps it’s time the fertilizer industry took a closer look at this low-cost, lightweight, and natural raw material.

Photo credit: Academia, Popsci, Phys.org, & Insideurbangreen