Anyone wanting to produce carbon nanotubes, nanowires, nanorods, or sheets of nanomaterial needs to understand which process produces which structure. But now a team from the University of Bath in England has developed a single flow method which is ‘tuneable’ to achieve different forms and morphologies. While the full impact of the discovery is not yet known, it is believed that the new structures created, together with the process itself, could have a large impact on the manufacture of optics and sensors.

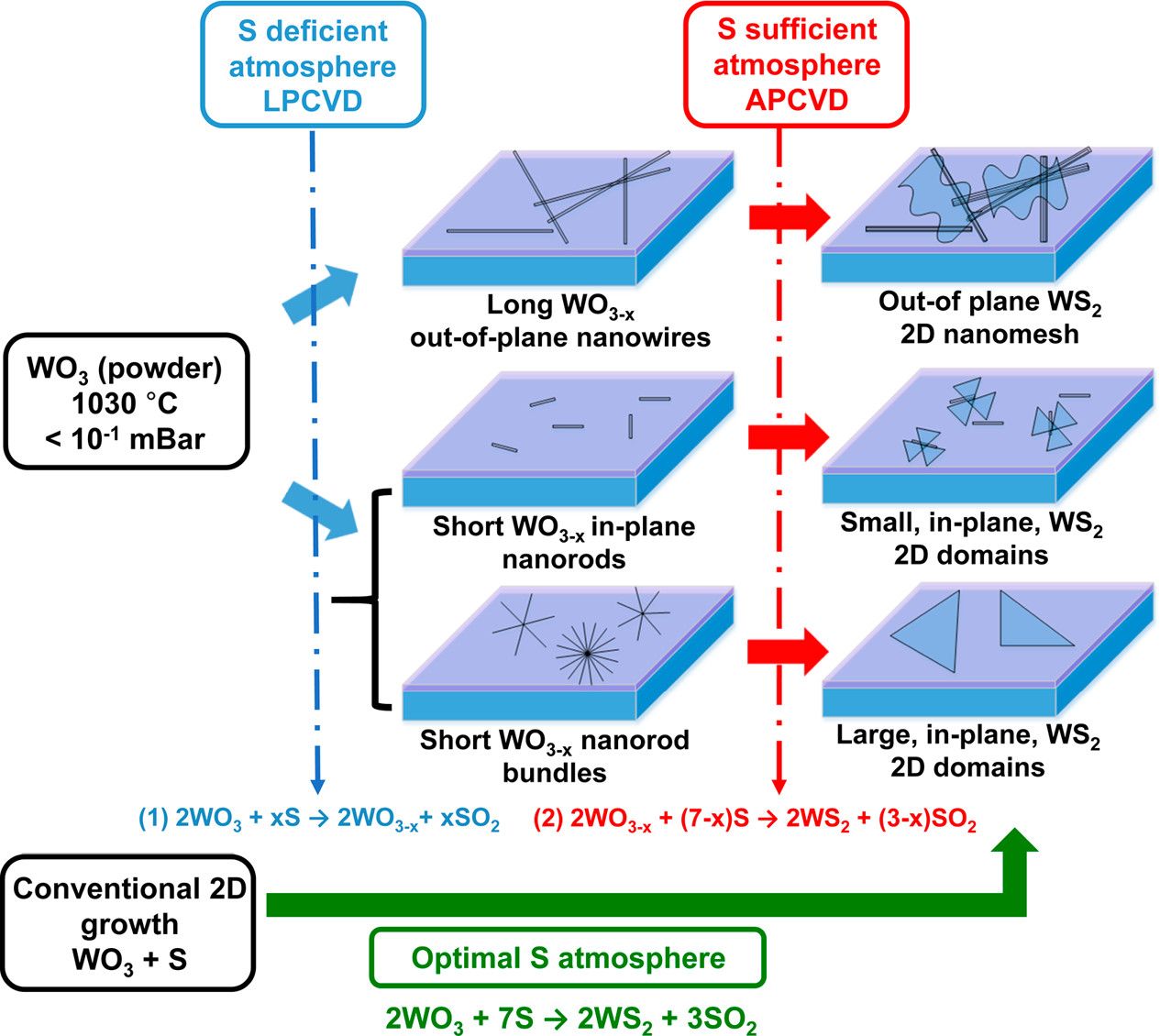

The study has now been published in the journal ACS Nano, where the researchers outlined the problem with traditional nanomaterial production as follows; “In conventional 2D growth via CVD [chemical vapour deposition], the operational window for optimal, monolayer growth is very narrow.” The challenge is when to add the sulphur vapour to the mix. As the study asks, “How early is too early? How late is too late?”

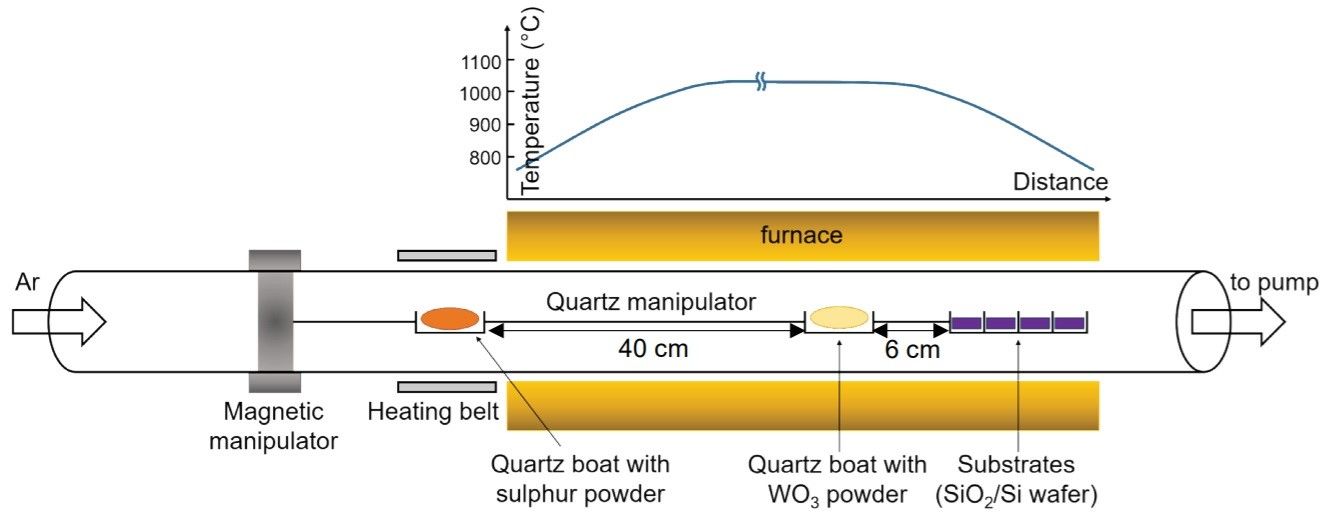

The new process avoids this problem by using a Tungsten Disulphide – a Transition Metal Dichalcogenide (TMD) that can be synthesized on insulating planar substrates without the need of a catalyst. The scientific journal Phys.org describes TMDs as, “layered materials which in their two-dimensional form can be considered the inorganic analogues of graphene”.

The process is technical, but the university website outlines it as follows, “The various Tungsten Disulphide morphologies synthesized are possible due to … splitting the growth process into two distinct stages. Through this decoupling, the growth process could be routed differently than in more conventional approaches and be guided to produce all these material morphologies.”

The result is a variety of nanomaterial structures including, “Two-dimensional sheets growing parallel to the substrate, nanotubes, or a nanomesh resembling a ‘field of blades’ growing outwards from the substrate.”

Of particular interest to the nanotechnologists is the ‘field of blades’ morphology, which has shown powerful optical properties, including strong non-linear effects. This includes a property called ‘the Second Harmonic Generation’ which is a doubling of the frequency and halving of the wavelength of laser light, changing its colour as it does so.

As Dr Adelina Ilie, from the University of Bath’s Department of Physics, who led the research, notes, “The ‘field of blades’ morphology is entirely new, and due to its very large effective surface area, might be of interest not only for the non-linear optical properties we showed so far, but also for application in various sensing technologies. We are exploring all these avenues now.”

Ilie is rightfully proud of her team’s discovery, as she explains, “The simplicity of this process is important from the standpoint that it allows us to obtain practically all phases of this Transition Metal Dichalcogenide, from in-plane to out-of-plane, as well as from two-dimensional sheets to one-dimensional nanotubes and everything between. Usually different processes are used to create two-dimensional or one-dimensional morphologies. Our process, instead, leads to tunable materials with tunable properties.”

Professor Ventsislav Valev, who tested the nanomesh for optical properties is similarly enthusiastic about the new qualities the new structures possess, stating, “We are talking about a material that is one or two atoms in thickness; it is quite extraordinary. Its arrangement into a ‘field of blades’ clearly increases the signal.”

In fact, Valev even admits that the full potential of this process and the nanomaterials that it can synthesize is not fully known, even by the team that created it. “We haven’t actually been able to test the upper limits of the optical effects yet because the signal is too strong for the equipment we used to probe it.”

Untapped potential indeed!

Photo credit: BathUniversity, Phys.org, ACS Nano