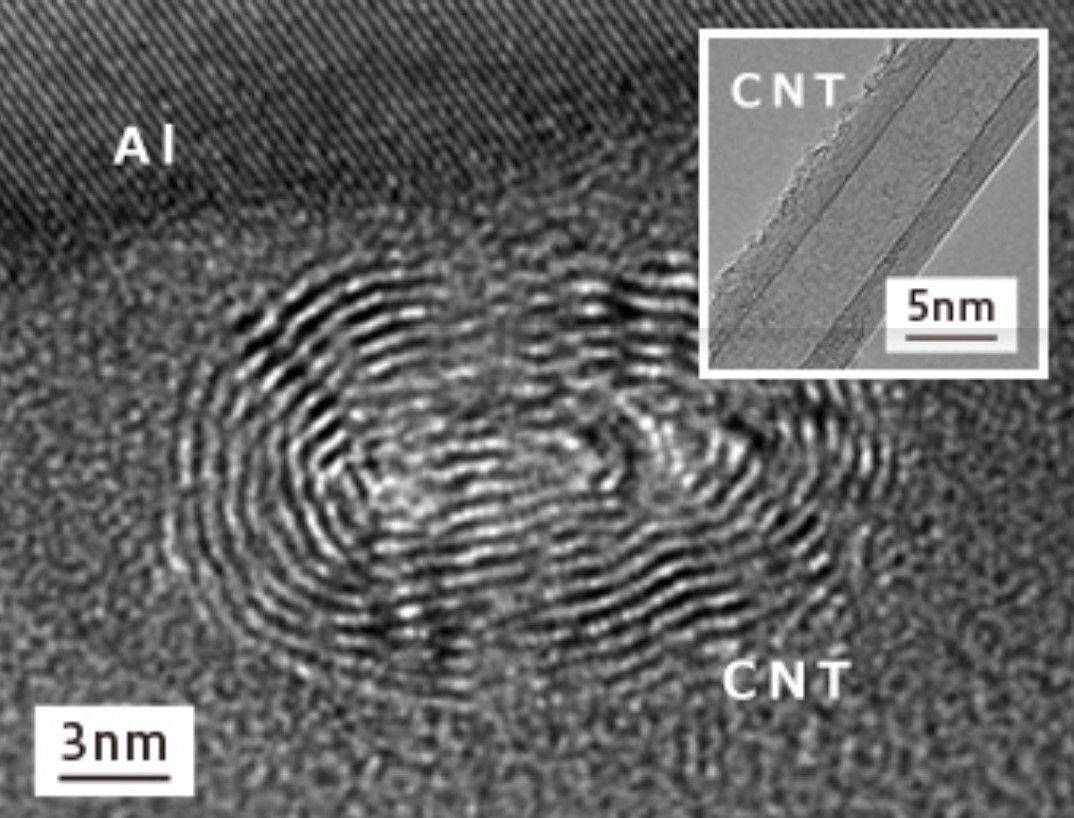

Onto the long list of current uses for nanotubes must now be added the possibility of replacing copper in wires with an aluminium/nanotube composite. This is because a team of researchers from California have developed aluminium wire rods strengthened by carbon nanotubes (CNTs), that form a lighter, cheaper alternative to electrical wiring in vehicles.

The discovery is likely to further boost the emerging carbon nanotube industry, as acceptance by major car manufacturers of the cost savings and property advantages (strength, flexibility, conductivity, low weight) will be a high-profile use for CNTs.

Nanotechnology involves the use of materials on a minute scale (1mm = 1 million nanometres). The width of a human hair is about 100,000nm.

In 2011, the EU adopted a legal definition for nanomaterials, defining them as, “A natural, incidental or manufactured material containing particles, in an unbound state or as an aggregate or as an agglomerate and where 50 % or more of the particles have one or more dimensions in the size range of 1 nm - 100 nm.”

Materials used at such a tiny scale have different properties and special advantages over those used in bulk.

For example, a gold bar must be heated to 1,064oC before it starts to melt. But the same gold bar in a nanoform will melt at 591oC.

This latest breakthrough was made by a team of scientists at the vehicle wire harness manufacturer Yazaki’s research and development subsidiary - YTC America.

“By drawing the rods down to fine wire, the strength increases further, hardening to a strength similar to copper wire,” says Stefan Maat, the director of materials research and development at YTC America. “In fact, it exhibits a strength surpassing that of steel.”

The automobile industry has long hoped to replace copper wiring with a cheaper, lighter aluminium alternative. However, copper’s strength and conductivity has meant that car manufacturers had to continue buying between 15 to 30 kilos of the more expensive copper for every vehicle they make.

As the industry journal Auto News reports, “ “The raw material cost of an aluminum wire is only about 15 percent of that of copper wire, but aluminum offers only 60 percent of copper wire's conductivity. And the tensile strength of aluminum is just 25 to 30 percent of that of copper.”

Furthermore, carbon nanotube materials possess superior heat resistance, a factor that often needs to be considered in car parts.

As the industry journal Aluminium Insider highlights, “Whereas ordinary aluminium wire is incapable of handling temperature much higher than normal, aluminum carbon nanotube material is able to withstand high heat resistance, allowing it to be utilized for high-current applications like electric vehicle battery cables.”

This discovery is another clear example of how research into carbon nanotubes is resulting in practical solutions to engineering problems. This is especially true in the field of material development, where the use of CNTs in making new composites with metal, plastic, and ceramics (among others) is bringing improvements to all areas of manufacturing, pharmaceutical, construction, agriculture, and medical industries.

Photo credit: Aluminiuminsider, Autonews, Copperalliance, Yazaki, & Gses