As any engineer will tell you, a massive amount of heat energy is wasted by machines and devices. So much so, that fans and cooling devices are often employed to remove the heat from computers, car engines and mobile phones. But now a team of nanotechnology specialists have invented a nanomaterial that allows for the capture of heat energy and its conversion into electricity; a nanomaterial of incredible value.

Previous attempts at creating waste heat to electricity substances have required energy-intensive production processes that made the resulting substances prohibitively expensive.

Meanwhile, in June 2019, the journal Science Daily reported that, “By one official estimate, American manufacturing, transportation, residential and commercial consumers use only about 40 percent of the energy they draw on, wasting 60 percent. Very often, this wasted energy escapes as heat, or thermal energy, from inefficient technology that fails to harvest that potential power.”

However, the basic theory behind thermoelectric materials is simple; when one side of the material in hot, the other is cold causing an electrical charge to build up along the temperature gradient. If this charge could be effectively captured, it could revolutionise the way we power any device or machine that gets hot.

Yet, despite such a simple process, studies of thermoelectric materials are few and far between. As Mohamad Nugraha, a postdoctoral researcher and co-author of the breakthrough study makes clear, “Among the many renewable energy sources, waste heat has not been widely considered.”

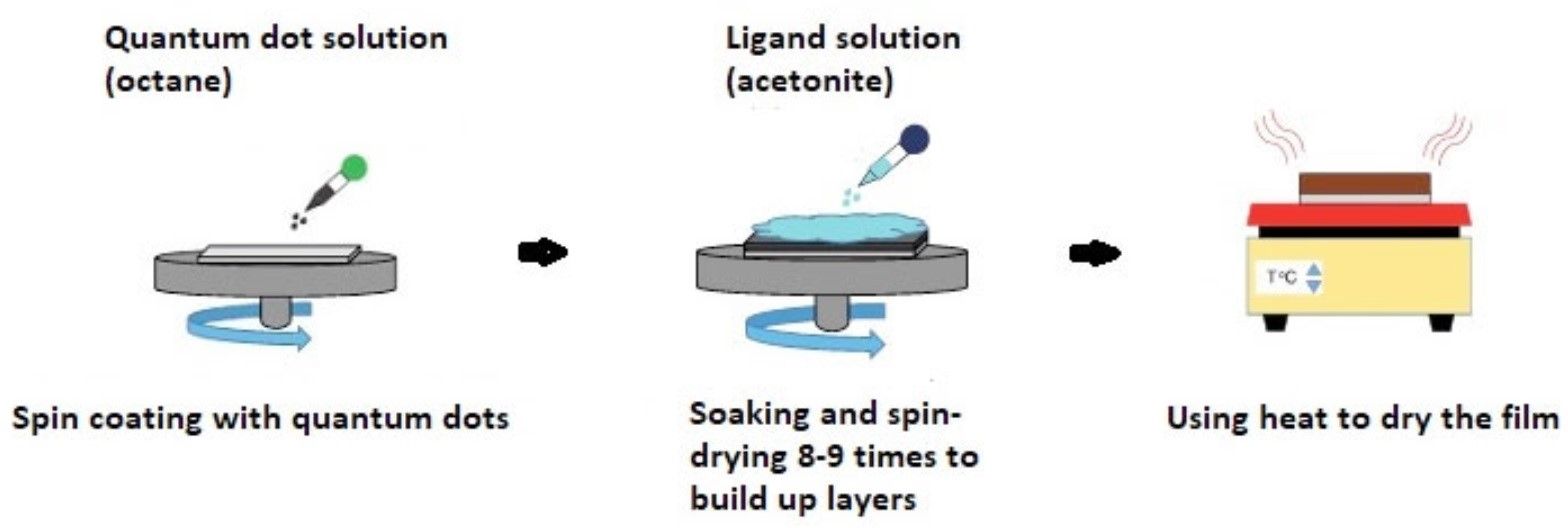

But now Nugraha, working with colleagues at the Derya Baran Lab at the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia, have developed a new thermoelectric material made by spin coating a liquid solution of nanomaterials called quantum dots.

“Among the many renewable energy sources, waste heat has not been widely considered,” says Mohamad Nugraha, a postdoctoral researcher in Derya Baran's lab. Waste heat emitted by machines and devices could be recaptured by thermoelectric materials.

As the nanotechnology journal Nanowerk, explains, “The team spin coated a thin layer of lead-sulphide quantum dots on a surface and then added a solution of short linker ligands that crosslink the quantum dots together to enhance the material’s electronic properties. After repeating the spin-coating process layer by layer to form a 200-nanometer-thick film, gentle thermal annealing dried the film and completed fabrication.”

The teams findings have now been published in the journal Advanced Energy Materials, where they report how, “Colloidal quantum dots (CQDs) demonstrate to be promising materials to realize high‐performance thermoelectrics owing to their low thermal conductivity.”

The study also describes how earlier research focused on making thermoelectric materials through a process that used high temperatures, stating that, “The most studied CQD films, however, are using long ligands that require high processing and operation temperature (>400 °C) to achieve optimum thermoelectric performance.” Instead, the KAUST team made a breakthrough in finding that, “CQD films cross‐linked using short ligands that allow strong inter‐QD coupling are reported [to provide thermoelectric properties].”

As Nugraha notes, “[Previously] Thermoelectric research has focused on materials processed at very high temperatures, above 400 degrees Celsius.” Whereas the new method heats up the materials to only 175 degrees Celsius, not only reducing production costs but allowing the coating to be applied to a wide variety of different materials, even cheap flexible plastic. It can even generate power from very small temperature differences.

Ultimately, not only could this nanocoating provide a real-world solution to powering electronic devices, but it shows how the nanomaterial industry is on the cusp of changing our macroworld … forever.

Photo credit: Wileyonlinelibrary, & KAUST