A research team from Washington State University have made a replacement for Styrofoam made from the plant material cellulose. With comparable qualities to the brand-named product yet made from an environmentally friendly and easily sourced raw material, this new foam makes an excellent addition to the circular economy.

The original Styrofoam is a versatile and useful material. It has good insulating properties and is widely used in products such as disposable coffee cups, takeaway food boxes, drink coolers, handicraft projects, or, due to its cushioning effect, as a packing material.

It is a successful part of the part of the Dow portfolio, with 3 million tons manufactured annually (Americans alone use around 25 billion Styrofoam cups).

However, it is also a petroleum-based product, made from expanded polystyrene foam, giving it a high environmental price.

When burnt it gives off toxic fumes and it takes years to degrade naturally if placed in landfill. Whilst it is possible to recycle Styrofoam, it is a complex, expensive process and most local authorities do not have the necessary facilities, so it is typically added to a non-recyclable waste stream. The US EPA estimates that as much as 80% ends up in landfill, with much of the remainder ending up in waterways and oceans.

With its plant-based feedstock, the replacement foam has much better eco-credentials and yet still reaches practical standards achieved by the fossil-fuel based original, something which has previously eluded scientists.

As the Washington State University website explains, “While other researchers have created other cellulose-based foams, the plant-based versions haven’t performed as well as Styrofoam. They are not as strong, don’t insulate as well, and degraded at higher temperatures and in humidity.”

Additionally, the nanocellulose foam holds the following advantages;

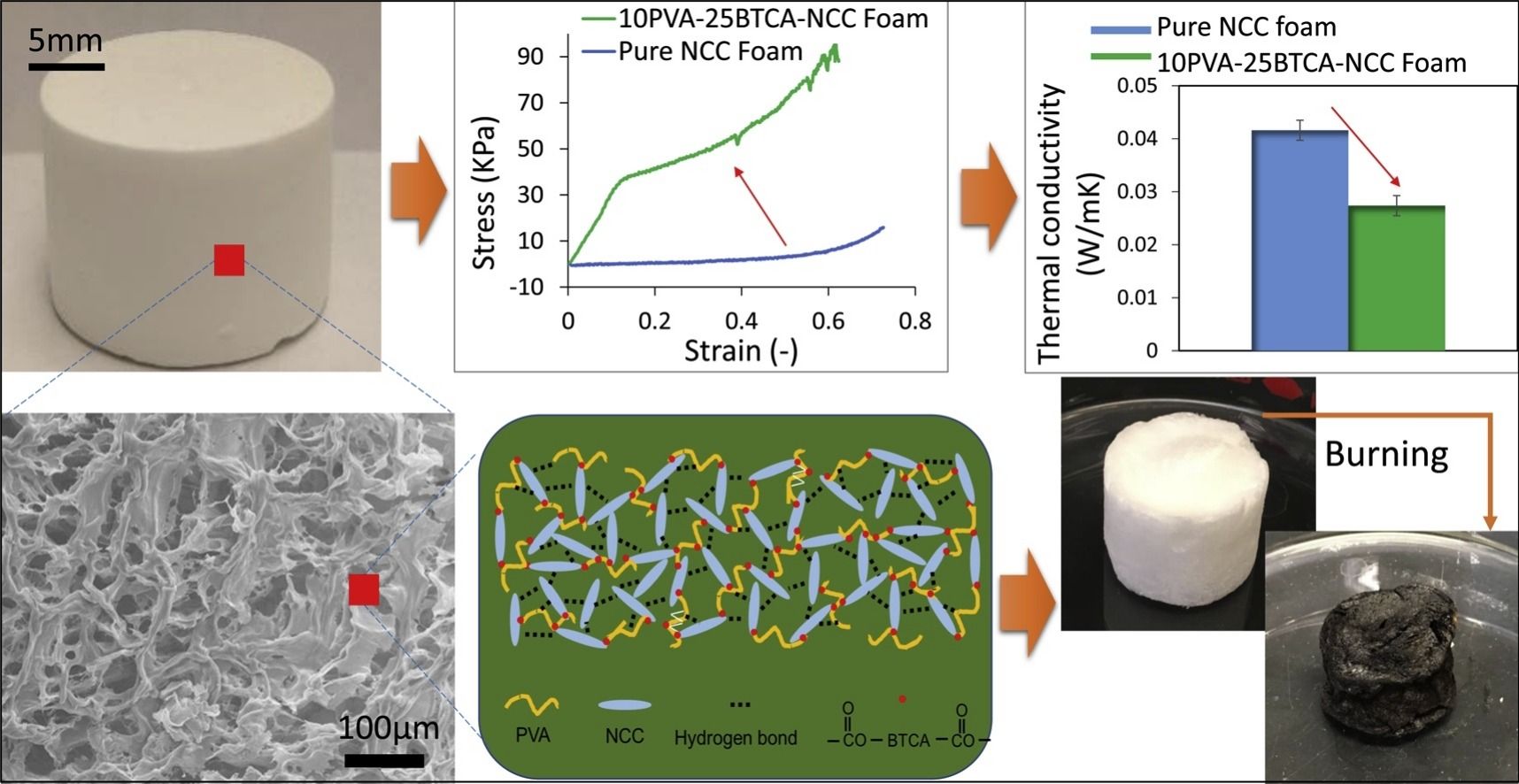

· It is fabricated in a simple process using only water.

· It maintains excellent heat-insulating properties.

· It is durable, and performs well when tested for compression, tension, elasticity, and strength.

· The structural integrity is preserved even after burning.

As Amir Ameli PhD, the study’s co-author, states, “We have used an easy method to make high-performance, composite foams based on nanocrystalline cellulose with an excellent combination of thermal insulation capability and mechanical properties.”

However, beyond finding a replacement for Styrofoam, the researchers hope that the discovery will lead the way in exploring nanotechnology applications for cellulose.

“Our results,” says Amir, “demonstrate the potential of renewable materials, such as nanocellulose, for high‑performance thermal insulation materials that can contribute to energy savings, less usage of petroleum-based materials, and reduction of adverse environmental impacts.”

Amir’s fellow co-author Dr Xiao Zhang, agrees, describing the discovery as, “… a fundamental demonstration of the potential of nanocrystalline cellulose as an important industrial material.”

The results have now been published in the specialist journal Carbohydrate Polymers, where they define the new substance as being, “… composed of nanocrystalline cellulose (NCC) (74 wt%), polyvinyl alcohol (7.5 wt%), and a crosslinking agent (18.5 wt%).”

Adding that, “The composite foams exhibit an elastic strain of ˜13% at a modulus of 250 K Pa and a stress of 73 K Pa at 50% strain (100+ and 18 times, respectively, higher than those of pure NCC foam); both exceed the values of reported nanocellulose-based foams with no reinforcement. The foams exhibit a thermal conductivity of 0.027 Wm−1 K−1, which is superior to those of traditional insulating materials.”

With funding from the U.S. Department of Agriculture and WSU’s Office of Commercialization, the team now plan to develop stronger and more durable formulations focusing on specific practical applications. The team is also considering how to adapt the process for industrial-scale production and getting a product on the market.

These are interesting times for nanotechnology entrepreneurs, with new products and applications frequently being found for nanotubes, nanoparticles, nanowires, and now nanocrystalline cellulose.

As Zhang observes, “This promising material has many desirable properties, and to be able to transfer these properties to a bulk scale for the first time through this engineered approach is very exciting.”

Photo credit: ScienceDirect, NorthernRecycling, Goevergreen, & WSU