Researchers from Saarland University in Germany have applied a nanocoating onto a synthetic foam creating a material strong enough to absorb bomb blasts.

Additionally, by varying the material used in the nanocoating, the foam can be used as a raw material for construction, car and aeroplane manufacture, bomb-proof screens, or even sound reduction cladding. All from a structure that mimics the interior of bones, as the Saarland University press release describes, “The inspiration for the new foam system came from nature. Strong enough not only for use in impact protection systems in cars, but able to absorb the shock waves produced by a detonation. Those are just some of the properties shown by these metallic foams.”

While synthetic foams have long been known for their strength and lightness, their porous, open-cell structure is complex and difficult to manufacture, making them expensive. At the same time, the sponge-like interior is often still too weak and not resilient enough for a number of applications. This is especially true for the most commonly produced synthetic foam which is made of aluminium.

"This is the reason why metal foams have so far not had any real market impact," explains materials scientist Stefan Diebels, the study’s co-author and professor of applied mechanics at the world-leading material science department at Saarland University.

Yet with rising raw material costs and a growing need for stronger, lightweight components, the development of synthetic foams is a high priority for many industries.

As the research, now published in the Wiley Online Library outlines, “Based on an increasing demand of energy and raw materials, resources should be used more efficiently. Therefore, multifunctional materials and lighter constructions, which can endure higher payloads, are needed. Cellular materials like metal foams are bionic, multifunctional materials.” This made them ideal candidates for the research.

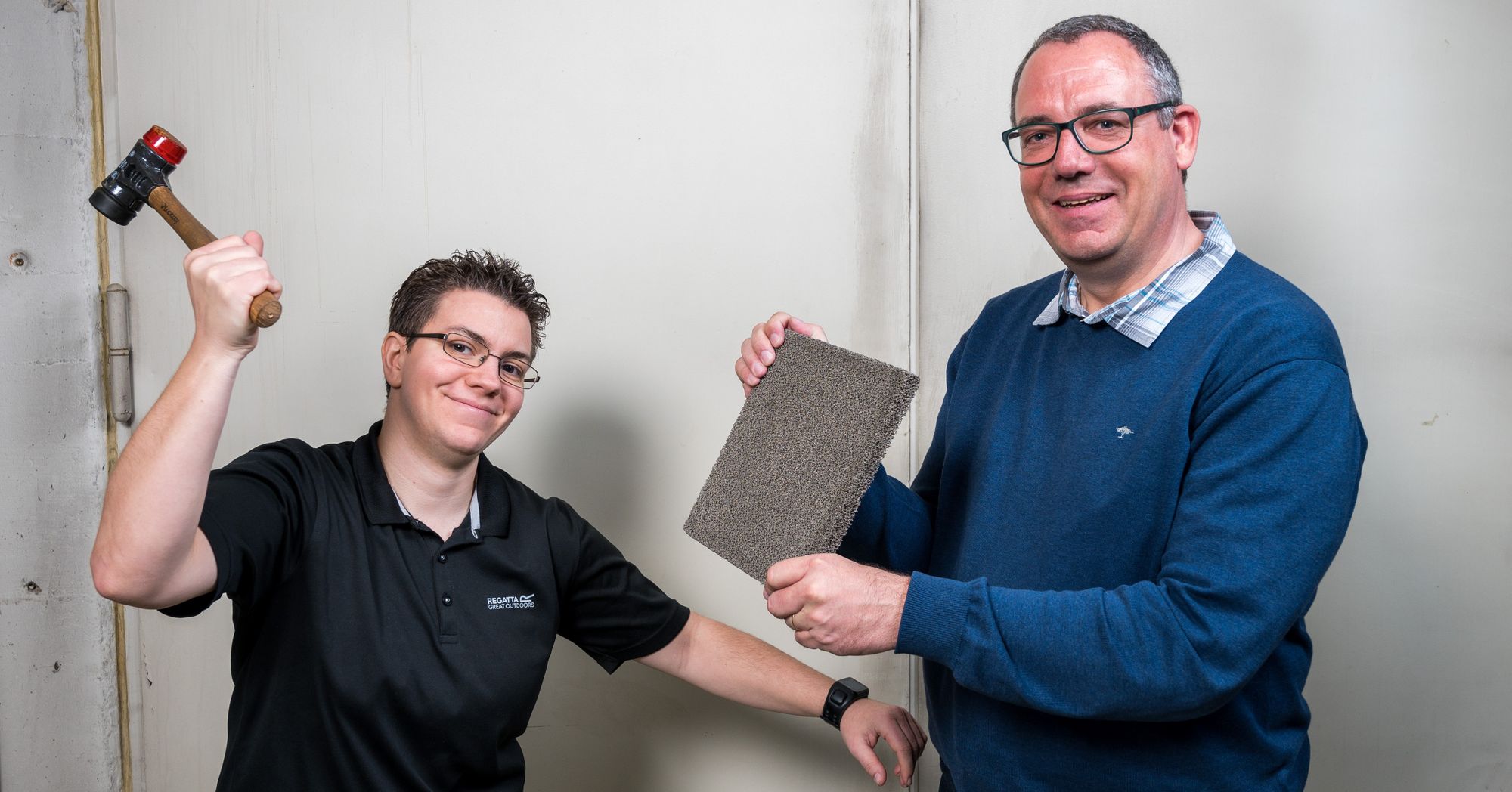

The discovery was made by Diebels in cooperation with Dr Anne Jung, who together found that applying a nanocoating to the interior lattice network gave the foam incredible properties of strength, shock absorption, and sound suppression while maintaining low weight.

The biggest challenge was how to apply the coating evenly on the inside of the metal foam.

“The problem,” says Jung, “is that the metallic foam acts as a Faraday cage.”

This was solved by a novel (and now patented) coating method which is based on an electroplating bath. As the industry journal Manufacturing, reports, “As the interior of the foam is surrounded by electrically conducting material, electric current and thus the coating is diverted to the exterior of the foam body and does not travel through the interior of the foam—it's similar to what happens when lightning strikes a car.

The breakthrough came when Jung decided to use a special anode cage, which allows her to apply a uniform, nanocrystalline coating throughout the entire lattice network.”

The result is a significantly stronger synthetic foam with more stable interior struts and a lattice network with a greater load-bearing capacity.

As Diebels states, “The resulting metal foams have a low density, a large surface area but a small volume. In relation to their weight, these foams are extremely strong and rigid.”

“The patented method also functions on an industrial scale with foams with very large surface areas,” adds Jung.

Earlier experiments were based on aluminium foams, as they are an industry standard, but the team has now progressed to working with polyurethane. Not only is this a much cheaper material, but as a polyurethane foam gains most of its strength from the thin metal coating applied to the lattice structure, it is an ideal way to prove and test the nanocoating’s capabilities.

Already the material has been used in the construction of mobile barriers to provide protection from the shock waves of an explosion. Even underwater, the material was an effective cushion against the pressure and sound waves of a detonation, simply ‘swallowing’ the shock waves and defending sensitive marine organisms.

“Most of the applications we focus on are generally less spectacular, such as the use of our foams in lightweight construction,” notes Jung.

The team are also exploring the material’s application in the load-bearing structure of cars and aeroplanes.

“They can be installed as reinforcing struts in the bodywork, while also providing impact protection. The struts can take up large amounts of energy and are able to absorb the force of a collision when parts of the porous core fracture under impact,” explains Jung.

However, other possible applications include using it as a heat shield; as sound-proof cladding; in advanced building design and architecture; or for electromagnetic screening. It could also be applied in the chemical industry as a catalysis, because the material is porous, so liquids and gases can easily flow through creating a potential mixing-ground for chemical reactions.

Additionally, the team have experimented with different nanocoatings. As Manufacturing journal reports, “Using an array of experiments, simulations, tension and compression testing, optical microscopy, and x-ray computed tomography, the research team have examined the structure, pore geometry and curvature of the struts and have shown how varying the thickness of the nanocoating can impart different properties to the foam materials. By varying the composition of the coating, its thickness or the pore size, the team is able to customize foams to meet different application needs.”

This has led the team to discover that an open-cell lattice structure with a nickel nanocoating creates particularly strong foams, while a copper coating makes a foam which exhibits high thermal conductivity. A silver nanocoating has good antibacterial properties, whereas using gold is highly decorative.

With the research work ongoing, engineers are beginning to dream of what properties they would wish for in a next-generation synthetic foam.

Photo credit: Thermalspray, Saarland University, Reddit, DailyMail, & NewAtlas