The automobile industry may soon have a new raw material to source following the announcement of the successful testing of a pneumatic tyre made with graphene. This breakthrough technology could create a new niche market for tyres, reduce environmental impact, and make driving cheaper. Further proof of the versatility of nanomaterials.

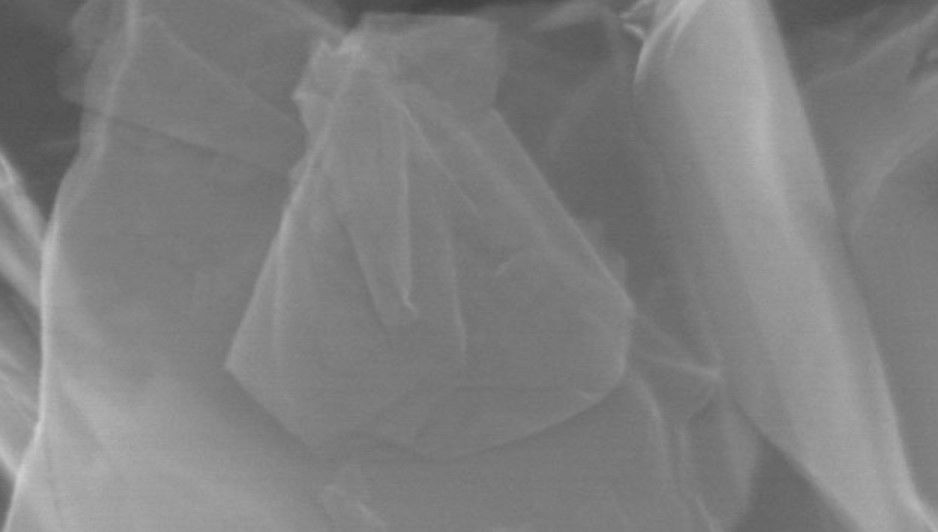

The tyres were developed over an 18-month period, as a cooperation between two companies; one Canadian and one British. Toronto-based Gratomic produced graphenes of “high purity, consistency, and scalability” with graphite from its mine in Namibia. While in the UK, Perpetuus Advanced Materials developed a production method which the company’s press release describes as “… a patented plasma process to produce hybrid graphenes with less than 10 layers, which are then incorporated in tyre elastomers for the development of graphene ultra-fuel efficient tyres.”

A major part of the product development included a 6-month terrain test with independent third-party supervision, comparing the graphene-based tyres against conventional ‘premium’ tyres from a globally recognised ‘household name’ brand.

As a report published in the European Rubber Journal, explains, “The tyres were fitted to high mileage, commercial light vehicles, which primarily travelled on A and B roads within the UK and the performance of the tyres was data logged throughout the entire test period. The results concluding that the tyres enhanced with surface engineered graphenes, produced a greater than 30% increase in wear resistance over the competing brand tyres.”

The industry standard testing, including dynamic mechanical analysis (DMA), also showed ‘a significant improvement’ in rolling resistance, an improvement in fuel economy of more than 30% (boosting miles per gallon), and shorter braking distances in both wet and icy conditions.

As Ian Walters, the COO Director of Perpetuus, noted, “The competitive terrain testing programme demonstrated advantages of including Gratomic’s graphite surface modified graphene fillers within tyre elastomers.”

Adding that, “… the investigative analysis and characterization have concluded that the graphene derived from the Gratomic mine are highly friable, [and] when functionalized have demonstrated excellent processability. Initial application in a host of end uses has demonstrated excellent suitability for a range of products. Most noteworthy are the excellent results generated when the Hybrid Graphenes are included in elastomers for tyre construction.”

“Purely from a demand perspective,” notes Gratomic’s CO-CEO Sheldon Inwentash, “we have been pulled into a market which represents a very large opportunity. Not only are Hybrid Graphene enhanced tyres fuel efficient, but they can also demonstrate better handling and longer life.”

This announcement is another example of how nanomaterials are changing the world for the better. Evidence of how the progress of nanotechnology is improving products and the quality of life. In this case, car tyres (which have experienced relatively slow innovation in the 131 years since Dunlop patented his pneumatic tyres) are now safer, more fuel efficient, and more durable thanks to nanoscale raw materials. Additionally, by lowering fuel consumption and lasting longer, they provide better value for money and are more environmentally friendly.

As further applications are found for nanomaterials, it is highly likely that the sourcing of graphene, carbon nanotubes, and nanowires will become as common place for manufacturing as the sourcing of copper and aluminium is today.

As Inwentash notes, “Simply put, our customers want what we have; high-quality graphene.”

Photo credit: Peoplematters, Perpetusaam, & Autowise