Lithium batteries are becoming more and more common. Found in mobile phones everywhere and growing in use in electric cars, lithium batteries are well known for their storage capabilities. Unfortunately, they are also known for catching fire, an event that battery experts call ‘thermal runaway’.

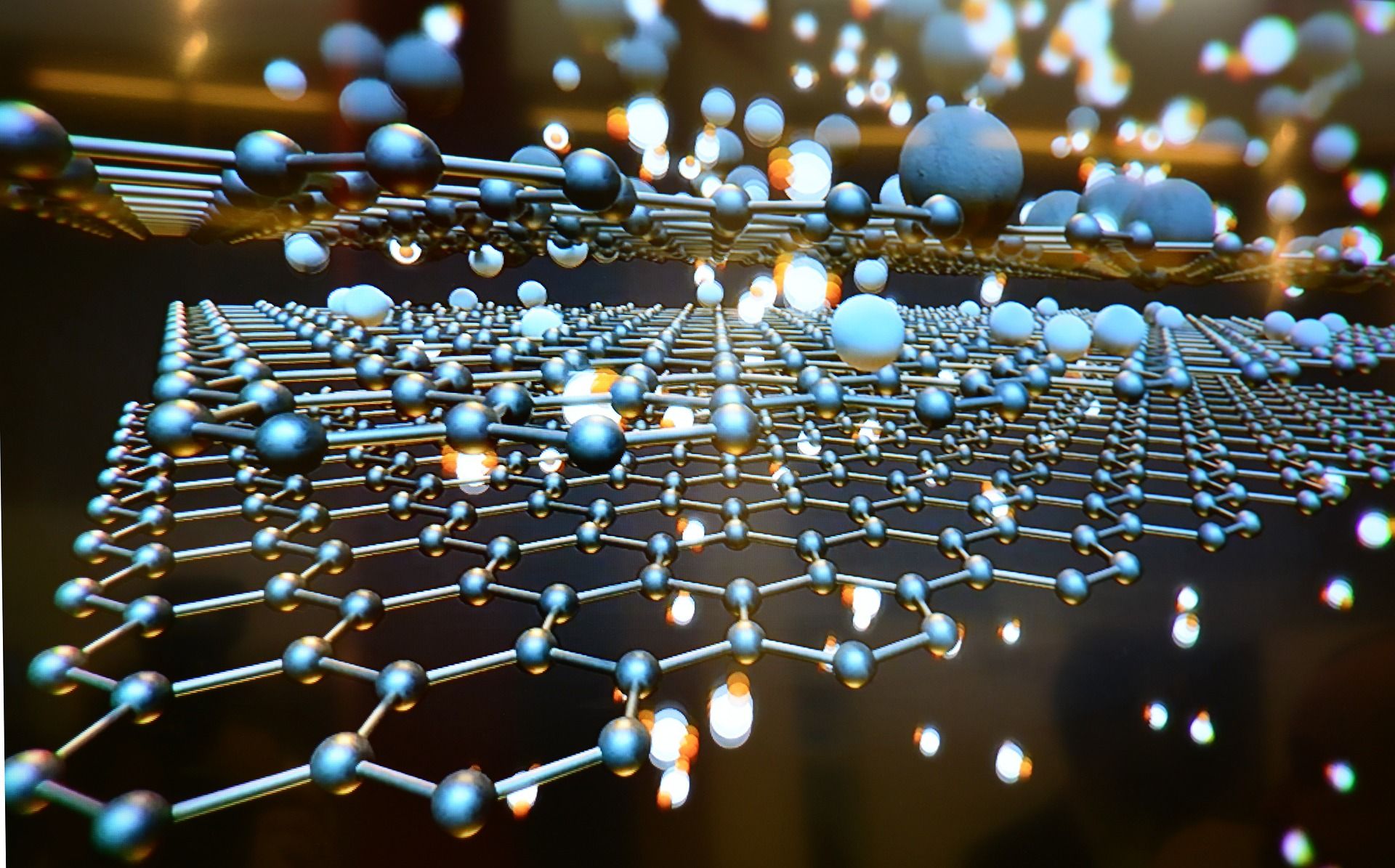

While lithium batteries do not often ignite, when it happens it often makes newspaper headlines, as phones in pockets or on airplanes, or cars travelling at high speed, pose a threat to safety. As a result, the battery industry is rapidly looking for ways to make lithium batteries safer, and a team of researchers from the University of Illinois at Chicago College of Engineering, believe they have found the solution; a graphene coating.

Lithium batteries usually catch fire during periods of rapid charging and discharging or when experiencing high temperatures. This causes the lithium cobalt oxide in the battery’s cathode to decompose and release oxygen. If this mixes, under heat, with flammable materials from the decomposing electrolyte, the battery can ignite.

Considering this chain of events, Reza Shahbazian-Yassar, associate professor of mechanical and industrial engineering at UIC and a co-author of the paper, says, “We thought that if there was a way to prevent the oxygen from leaving the cathode and mixing with other flammable products in the battery, we could reduce the chances of a fire occurring.”

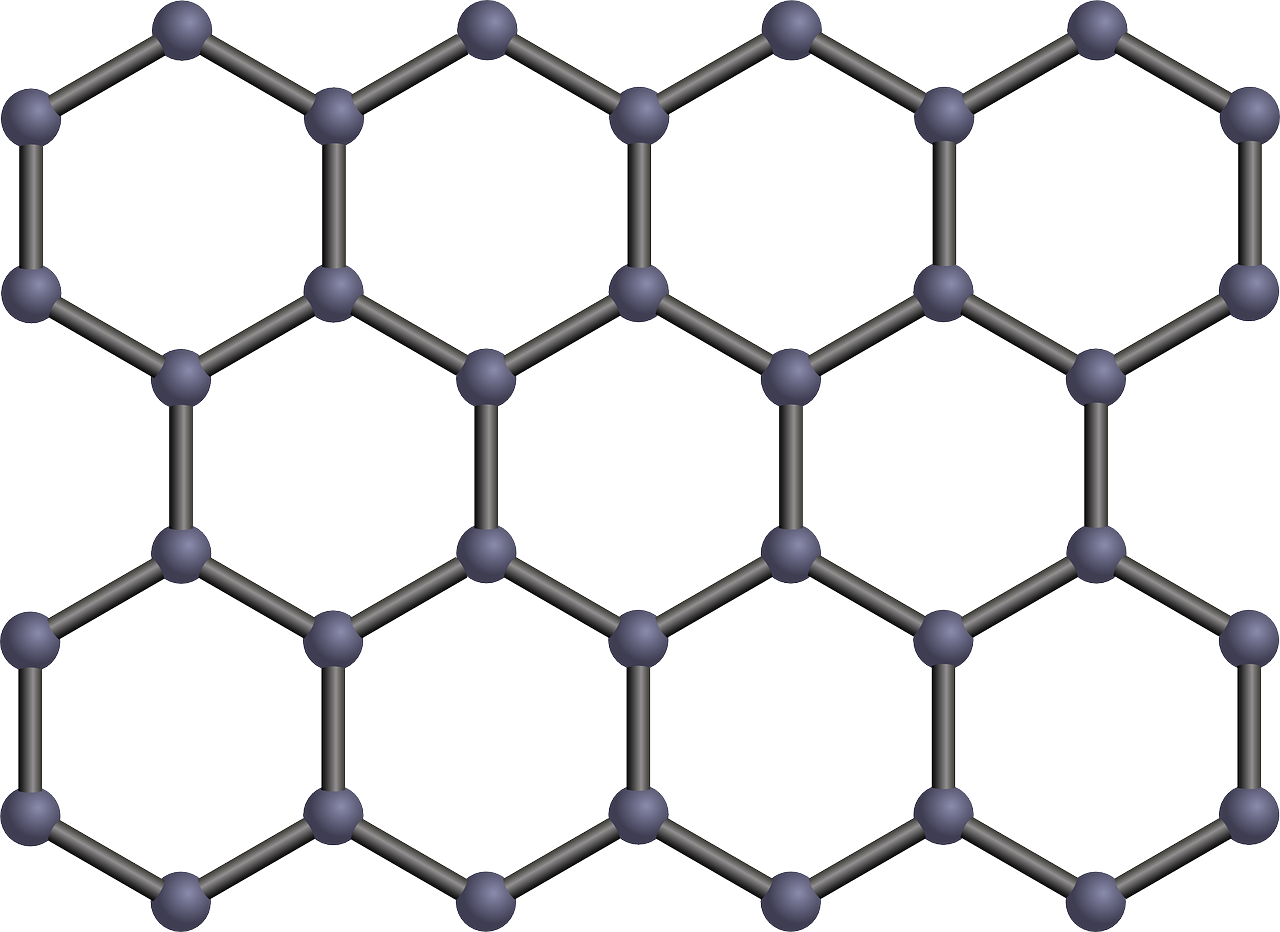

The team had already used graphene to help modulate lithium build-up on electrodes in lithium metal batteries. They also knew that graphene is strong, flexible, can be made electrically conductive and is impermeable to oxygen atoms. By using a graphene sheet to prevent the oxygen from mixing, the team could prevent battery fires.

The scientific journal Phys.org, explains the procedure as follows; “First, the researchers chemically altered the graphene to make it electrically conductive. Next, they wrapped the tiny particles of lithium cobalt oxide cathode electrode in the conductive graphene. When they looked at the graphene-wrapped lithium cobalt oxide particles using electron microscopy, they saw that the release of oxygen under high heat was reduced significantly compared with unwrapped particles.”

Finally, the team bound the wrapped particles together to create a usable cathode that they incorporated into a lithium metal battery.

Tests showed that there was almost no oxygen escaping from the cathodes even at high temperatures, and that the battery continued to perform well even after 200 cycles.

As Soroosh Sharifi-Asl, a graduate student in mechanical and industrial engineering at UIC and lead author of the paper, observes, “The wrapped cathode battery lost only about 14% of its capacity after rapid cycling compared to a conventional lithium metal battery where performance was down about 45% under the same conditions.”

The results have now been published in the journal Advance Functional Materials, where the researchers describe their discovery as, “… an advanced graphene nanocage structure with the capability of hosting both cyclo‐S8 and smaller sulfur molecules (S2–4).”

“Graphene is the ideal material for blocking the release of oxygen into the electrolyte,” says Shahbazian-Yassar. “It is impermeable to oxygen, electrically conductive, flexible, and is strong enough to withstand conditions within the battery. It is only a few nanometers thick so there would be no extra mass added to the battery. Our research shows that its use in the cathodecan reliably reduce the release of oxygen and could be one way that the risk for fire in these batteries - which power everything from our phones to our cars - could be significantly reduced.”

With lithium batteries predicted to become a $14 billion industry, any solution to the problem of spontaneous combustion could be worth millions.

Photo credit: Businesstraveller, Controlhazards, Arstechnica, & Phys.org,