The fertilizer industry is under a lot of pressure, as it is being asked to solve problems on several fronts.

In a nutshell these are;

1. A need for more fertilizer.

Population growth, reduced farming land available, increase in intensive farming (including winter cropping), and increasing use of sub-prime farmland.

2. Environmental challenges.

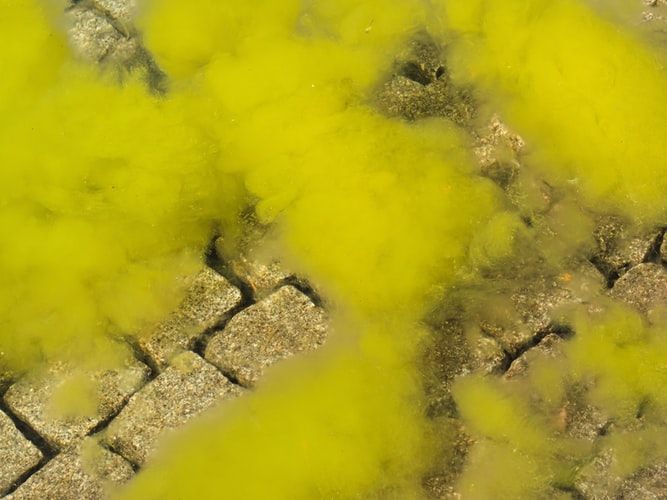

Overuse of fertilizer leading to damaged soils and ecosystems, fertilizer leaching and algal blooms, continued use of non-sustainable raw materials such as rock phosphate, energy intensive production creating greenhouse gases, and inefficiently long supply chains (for example the sourcing of rock phosphate from Western Sahara for American fertilizer production).

3. Infrastructure difficulties.

Regions of the world with greatest need for fertilizer, such as South America and Sub-Saharan Africa struggle to receive the fertilizer they need due to poor infrastructure, corruption, and bureaucracy.

4. Slow realisation of constructing new fertilizer production projects.

Traditional fertilizer production is done in bulk at huge processing plants. Building these facilities takes a lot of time and planning. As the Malaysian-based fertilizer company, Everchem observes, “The delays [in fertilizer facility construction] refer to the time lag from the date investment is obtained and orders placed to the date when production actually takes place. In developed countries this process typically takes up to 2 years, while in developing countries, 4 years.”

In a diverse and widespread industry, with thousands of fertilizer producers and raw material suppliers, and millions of farmers, none of these problems are easy to solve.

However, one word does go a long way to answer all the questions that the fertilizer industry is facing; nanofertilizer.

A more-widespread adoption of nanofertilizer would reduce environmental impact, by limiting the amount of runoff and algal blooming, reduce raw material demand (including the bulk quantities that create large amounts of greenhouse gases), and have a lower impact on soils and ecosystems.

Similarly, through improved application processes and design, such as slow release or moisture activation, less fertilizer will be required. Infrastructure challenges will also be eased as less bulk product needs to be delivered.

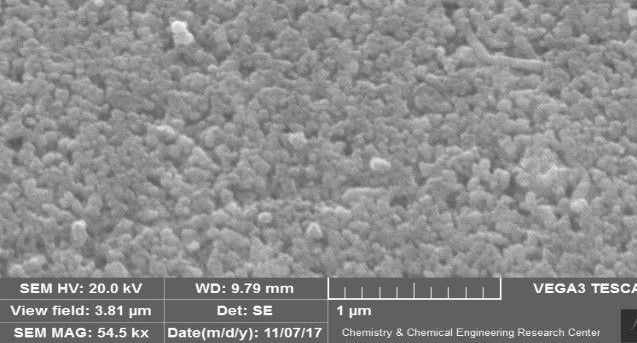

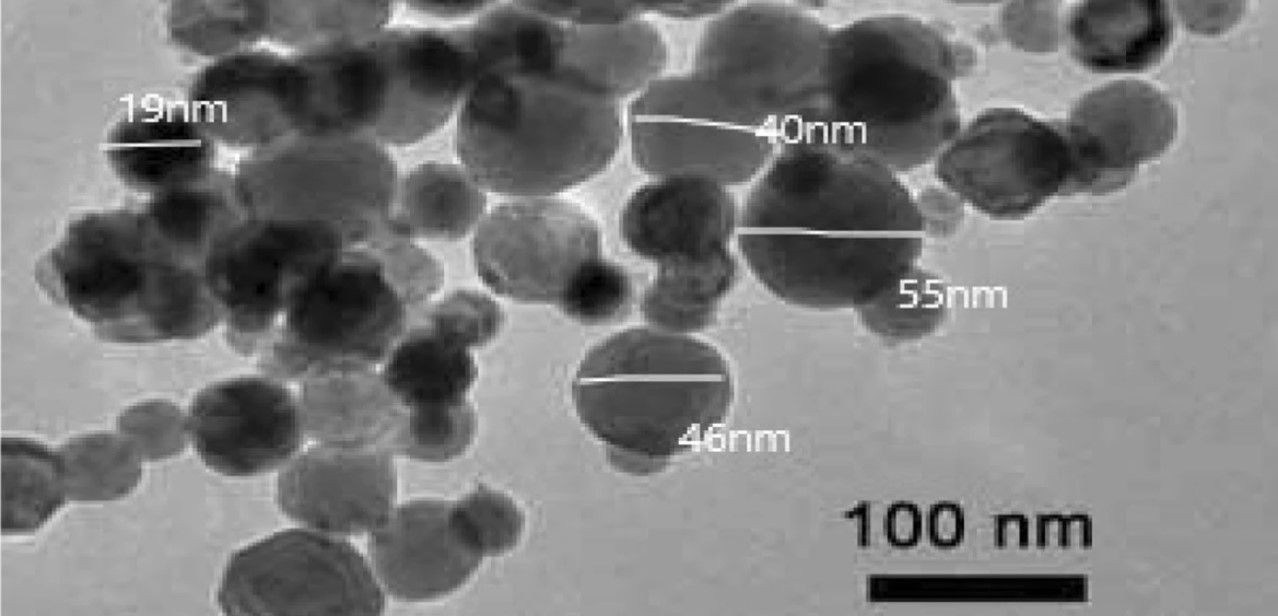

Nanofertilizers are based on particles measuring less than 100 nm (0.0001 mm), and come in three main classes:

Nanoscale fertilizer:

nanoparticles that contain nutrients.

Nanoscale additives:

traditional fertilizer with added nanoscale additives.

Nanoscale coatings:

traditional fertilizer coated nanoparticles.

Nature already contains naturally occurring nanoparticles, such as zeolites, which are also commonly applied as an industrial nanofertilizer. Other popular raw materials for nanofertilizers include, silver, copper, aluminium, carbon, zinc, potassium, nitrogen, and silica.

Recent studies are ongoing on the advantages and disadvantages of each specific nanofertilizer raw material, and their effects under different soil, crop, and climate types. For example, recent research has provided positive results for silver as both a beneficial supplement to plant growth and as a fungicide.

As a recent report by the MOJ Biology and Medicine states, “Biosynthesized silver nanoparticle (AgNP) applications have proven successful in performing two major tasks; plant growth enhancement and plant disease management. Therefore, it can also be concluded that silver nanoparticles are an efficient tool in providing green and eco-friendly alternatives [to bulk fertilizer]. They have antimicrobial activity against various plant pathogens as well as helping plants in absorbing important nutrients from the soil.”

To read more about this study then follow this link to the Team Trade blog Review of Silver as a Raw Material for Nanofertilizer Draws a Positive Conclusion.

Another, slightly unexpected source of raw materials for nanofertilizer has been the discovery of banana skins as a potent source of minerals. The research team, based at the National Research Centre in Cairo stating that, “In this investigation, it was found that the extract of banana peel contains about 80 g/L of elemental potassium chelated with citric acid. Also, other minerals such as iron, magnesium, copper, sodium, calcium, and manganese chelated with citric acid in a nanostructure form.”

Such a source of fertilizer raw materials has the added benefit of being easily derived from agricultural regions in parts of the world that are in greatest need of modern fertilizer products.

To read more about this study then follow this link to the Team Trade blog Banana Skins Used as Nanofertilizer Feedstock.

While the nanofertilizer industry is still developing, with new products and formulations being devised and tested each year, there are currently five main designs.

1. Slow release:

nutrients are slowly released over a period of time.

2. Quick release:

nanoparticles break up upon contact with a plant’s surface.

3. Heat release:

nutrients are released when the ambient temperature exceeds a set limit.

4. Moisture release:

released when in contact with water.

5. Specific release:

nutrients are released when in contact with certain enzymes or chemicals.

However, this list may grow, as analysis of the different routes available for crop nutrition in nanoform continues.

Significantly, this analysis includes a comparison of 78 academic papers on nanotechnology in agriculture which was published in the journal Nature Nanotechnology in May 2018. Called ‘A Critical Evaluation of Nanopesticides and Nanofertilizers Against their Conventional Analogues’, the work concluded that nanofertilizer has a, “… median gain in efficacy relative to conventional products of about 20–30%.”

This evidence, alongside the environmental, logistical, and demand-based advantages of nanofertilizer discussed earlier in this article outline the basis of this overview.

Nanotechnology has much to offer mankind, as carbon nanotubes, graphene, and nanowires play a larger and larger role in modern life. The special properties of elements at a nano scale offer a versatility and power that will influence all industries.

However, given the nature of plant life it is logical that nanoparticles and nanofertilizer will impact agrichemical producers more and more in the future as this is how crops make contact with the world. As the Taiwan-based, agricultural technology company Land and Green Technology, explains, “The fact is that the ions in water-solutions have a size of less than 1 nm and are freely transported inside the plants. However, according to research, plants can absorb particles up to 150 nm in size. Therefore, we can learn the effect of some nutrition elements by their sizes. This allows you to create a more complete balance of macro and microelements for plant nutrition in nano-fertilizers.”

Photo credit: Cosmosmagazine, TeamTrade, Wustl, Stefes, IJC, & Springeropen