In another exceptional month for nanotechnology, the industry has seen several discoveries on how nanotubes, nanoparticles, and now even ‘nanocubes’ will increasingly influence our world.

The discoveries include new uses in the mining industry and a use for nanoparticles as a ‘nanowrapper’ for carrying other substances. Plus, beyond the lab, there has also been significant investment into nanotechnology.

Here are some of the top breakthroughs in nanotechnology for February 2019.

Carbon Nanotubes find New Uses in Mining Industry

The mining industry is increasingly finding uses for graphene nanotubes. This is because of the raw material’s extraordinary qualities when used to make PVC plastisol.

As the industry journal Engineer Live reports, “With their unique properties, graphene nanotubes push PVC plastisol performance higher, to fully satisfy market demand for 105 – 109 Ω/sq resistivity, to preserve a permanent and stable form even after harsh working conditions, to maintain abrasion resistance, and to demonstrate flexibility in the colouring of final products. This all is possible with just 0.25–2 wt.% of graphene nanotube concentrate.”

This is leading mining companies to invest in equipment made of graphene nanotubes as a conductive additive. Applications include, nanotubes as a raw material for the manufacture of fibreglass mesh and ventilation ducting, as well as anti-static textiles and treadmill belts.

he growth in using nanotubes as a feedstock is due to its advantages over more traditional raw materials. Ammonium compounds offer only humidity-dependent resistivity and may become unstable over time. Carbon black ‘usually affects PVC plastisol’s mechanical performance very negatively’, whilst also turning products black. It can also make affect the ‘rheology’ or flow of liquid and semi-solid materials difficult during manufacturing, and it also attracts dust.

The use of graphene nanotubes can avoid all of these problems with a very low product input. Given all these factors it is easy to see why the mining industry is turning to nanotechnology.

Sabic Invests in Carbon Nanotube Business

The Saudi-based energy company Sabic has announced that it has bought a majority stake in the carbon nanotube company Black Diamond Structures (BDS). Established in 2014, in Austin, Texas, the firm’s main asset is its ownership of a technology called Molecular Rebar that is used to modify multi-walled carbon nanotubes (MWCNTs).

Explaining the significance of Molecular Rebar and the reason for their acquisition, a Sabic press release states that, “Conventional carbon nanotubes are known for their tendency to get entangled, cake and hold high residual impurities, limiting their capabilities of enhancing electrical and mechanical material properties in real world applications. In contrast, Molecular Rebar delivers clean, discrete carbon nanotubes of uniform aspect ratio, enabling their use to create high-performance energy storage applications.”

In an interview with the industry journal Plastics Today, BDS CEO John Hacskaylo, outlined how, “… the proprietary nanomaterial can be directly incorporated in existing production processes of batteries without requiring additional investments, allowing a fast track for manufacturers to improve their next generation of batteries.”

It is believed that Sabic’s purchase will enhance its product portfolio in the energy storage market, where it holds the potential for ‘game-changing benefits’ such as improved battery life, energy density, and charge rates. Beyond use in both lead-acid and lithium-ion batteries, the carbon nanotube technology also provides R&D opportunities for the development of specialty resins and functional compounds.

Scientists Develop Nanotechnology to Create Nanocubes for ‘Cargo’ Carrying

Scientists at the US Department of Energy’s Center for Functional Nanomaterials (CFN) have developed a technique that employs hollow metallic nanosized boxes to carry and release DNA-coated nanoparticles in a controlled manner.

Whereas most nanoparticles are solid objects, the ability to construct hollow nanocubes opens up a range of possibilities.

“Compared to their solid counterparts, hollow nanostructures have different optical and chemical properties that we would like to use for biomedical, sensing, and catalytic applications,” says, Fang Lu, one of the study’s co-authors at the CFN Soft and Bio Nanomaterials Group. “In addition, we can introduce surface openings in the hollow structures where materials such as drugs, biological molecules, and even nanoparticles can enter and exit, depending on the surrounding environment.”

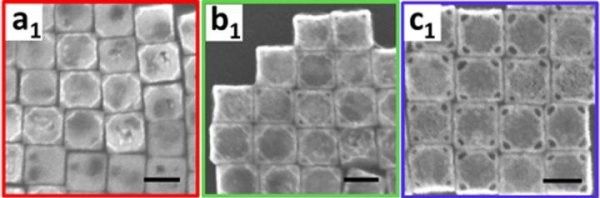

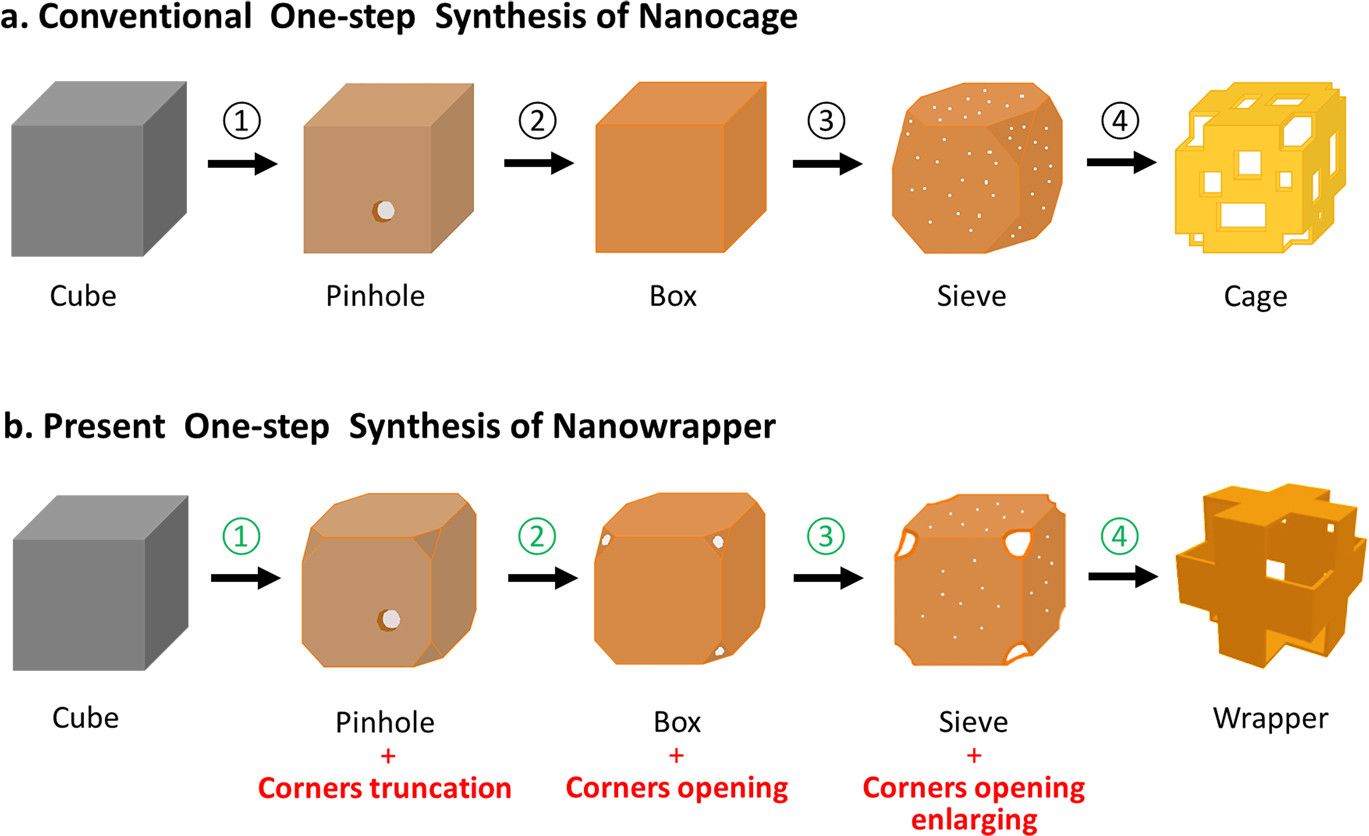

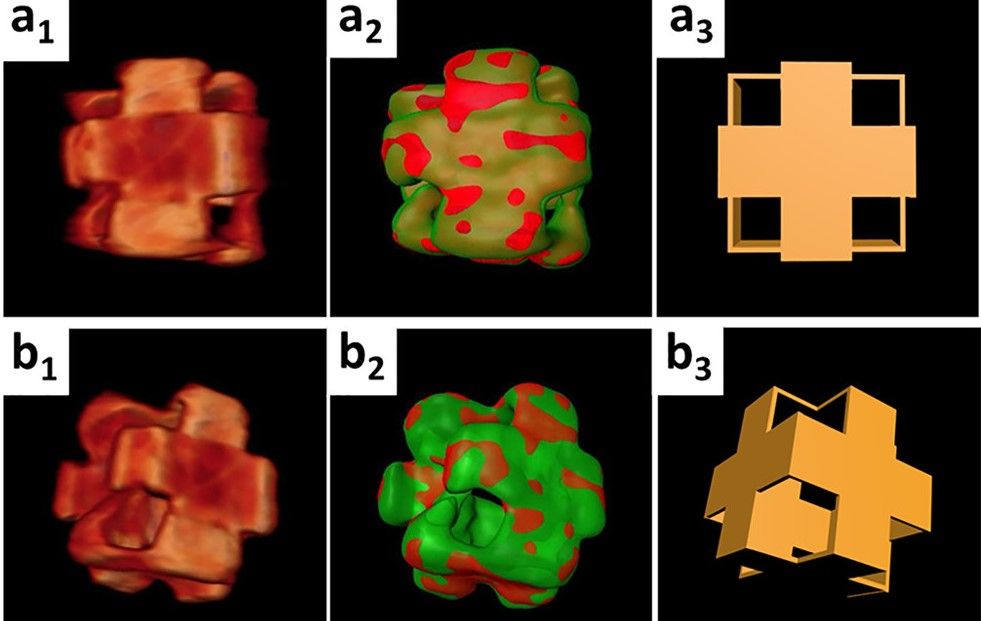

While hollow nanoparticles have been developed before, their ‘cargo’ entry and exit points have always been randomly placed pores or varying shapes and sizes. This gave them a ‘swiss-cheese’ appearance and limited their functionality. What makes this latest nano-delivery device special is that cargo can be loaded into the nanocubes through pores that are only located at the corners. Additionally, all the pores are square, giving the scientists considerable control over what is carried and when it is released.

Developing the concept further, the team have now manipulated silver nanocubes with gold to create ‘nanowrappers’ that can hold a variety of nanoparticles which can be control-released by light, heat, pH, or other chemical inputs.

The research was conducted at the Brookhaven National Laboratory whose website explained the process of constructing the nanowrappers as follows; “[The team] used a chemical reaction known as nanoscale galvanic replacement. During this reaction, the atoms in a silver nanocube get replaced by gold ions in an aqueous solution at room temperature. The scientists added a molecule (surfactant, or surface-capping agent) to the solution to direct the leaching of silver and the deposition of gold on specific crystalline facets.”

“Our electron microscopy and optical spectroscopy studies confirmed that the nanowrappers can be used to load and release nanoscale components,” said Lu. “In principle, they could be used to release optically or chemically active nanoparticles in particular environments, potentially by changing other parameters such as pH or temperature.”

“We did not expect to see such regular, well-defined holes,” says co-author and group leader Oleg Gang. “Usually, this level of control is quite difficult to achieve for nanoscale objects. Thus, our discovery of this new pathway of nanoscale structure formation is very exciting. The ability to engineer nano-objects with a high level of control is important not only to understanding why certain processes are happening but also to constructing targeted nanostructures for various applications, from nanomedicine and optics to smart materials and catalysis. Our new synthesis method opens up unique opportunities in these areas.”

The discovery has now been published in the peer-reviewed journal ACS Central Science.

The researchers are now studying how metals other than gold and silver work as nanocubes, as well as looking into making larger-scale structures by connecting multiple nanowrappers together. If successful, then nanowrappers could have a profound role to play in the pharmaceutical and medical industries. They also have potential as chemical sensors or for use as industrial catalysts in the chemical industry.

Photo credit: ACS Central Science, EngineerLive, MolecularRebar, & MIT