Carbon nanotubes may have found yet another application, as a team of researchers has found they possess great potential for use as a solid-state coolant.

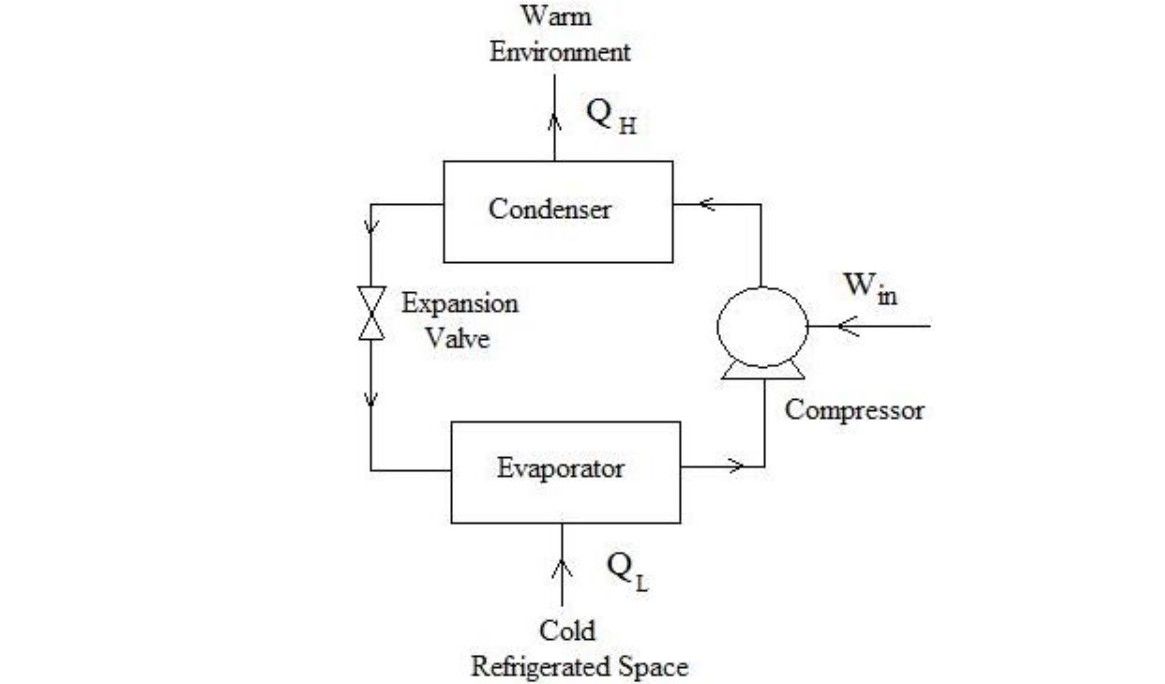

At present most refrigeration is conducted by vapor-compression refrigerators. This system works on a low pressure, low temperature liquid being converted to vapor, thus absorbing heat from the refrigerated space and keeping that space cool. When the vapor is then condensed to a liquid in a condenser, it gives off the heat to the surrounding environment.

This system is relatively simple, and very popular, being commonplace in many types of refrigeration systems, including freezers and refrigerators, as well as air conditioning units in buildings and cars. However, the chemicals needed to act as cooling agents are highly toxic and can kill if the system leaks. They are also damaging to the environment if not disposed off properly and can contribute to ozone depletion and climate change.

By using carbon nanotubes as a raw material, the team hope to offer a safer, less-toxic, and greener coolant.

As the research, recently published in the journal Annalen der Physik, states, “Solid‐state cooling is a young field of research with promising results toward the development of new, efficient, and environment friendly technology for a new generation of refrigeration devices. One of these methods is based on the so‐called elastocaloric effect (ECE), which consists of a temperature variation of a system in response to the application of adiabatic stresses.”

The elastocaloric effect (ECE) is defined by lead-author Alexandre Fonseca Ph.D. as a process, “… which makes use of temperature variations in a system in response to mechanical stress.” Much as a rubber or elastic band heats up if it is stretched and cools down when relaxed, so too can other substances heat up by mechanical manipulation. “The effect occurs if the deformation is applied to the material so that there is no heat transfer into or out of the system, i.e., when the process is adiabatic.”

To date the technology is still at a theoretical stage, although computer modelling conducted at the University of Campinas(UNICAMP) in São Paulo State, Brazil, has given very positive results, and the team are confident that can develop ‘an efficient and environmentally friendly alternative to vapor-compression refrigerators.’

"We began our research on the basis of an article entitled 'Elastocaloric effect in carbon nanotubes and graphene', published in 2016 by Sergey Lisenkov and collaborators. It described a computer simulation study showing that when a small deformation was applied to carbon nanotubes, corresponding to up to 3% of their initial length, they responded with a temperature variation of up to 30 °C," explains Fonseca.

"In contrast with Lisenkov's research, which simulated only simple strain and compressive force applied to the nanotubes, we reproduced the process computationally for a complete thermodynamic cycle. In our simulation, we considered two phases—nanotube strain and release—and two heat exchanges with two external reservoirs. We estimated the heat that would be extracted by the nanotube if it was in ideal contact with a certain medium. We obtained a good result for the performance coefficient compared with those of other experimentally tested materials."

The performance coefficient, as the online scientific journal Phys.org explains, is, “… the heat extracted by a system from a given region divided by the energy expended to do so. In the case of a household refrigerator, for example, it shows the amount of heat extracted by the appliance from the internal environment in proportion to the electricity consumed. The best household refrigerators have performance coefficients on the order of 8, meaning they transfer eight times more thermal energy from inside to outside than the amount of electricity extracted from the supply grid to perform the exchange.”

While the computer simulations for two different nanotubes showed coefficients of 4.1 and 6.5, Fonseca is quick to note that, “These are relatively good numbers compared with those for other heat exchange phenomena.” The results should also be expected to be low in such an early stage in the discovery process.

The carbon nanotubes are expected to be a long-lasting and durable raw material. If a stretching and releasing process were conducted on other materials, then over time the crystal structure of the material would change. Much as a rubber band can wear out and lose elasticity through use, so most solid-state coolants also gradually lose their effective properties.

However, according to Fonseca, “In the case of nanotubes, the process doesn't produce any structural transformations capable of causing defects. The atoms are separated during expansion and return to their original positions with relaxation.”

The tests also showed that carbon nanotubes have the ability to be stretched by as much as 20%. This coupled with their elastocaloric effects gives them great potential as a solid-state coolant, especially for use in electronic devices.

“The core problem in electronics is cooling. Our motivation was imagining a device that could use a simple cycle to extract heat from an appliance. Carbon nanotubes proved highly promising," he said. "They also have another virtue, which is that they're small enough to be embedded in a polymer matrix, a desirable property at a time when manufacturers are investing in research and development to obtain flexible electronic devices such as foldable smartphones.”

Photo credit: Brighthubengineering, Indiamart, Gizmodo, Medium, Fuelcellstore, & Neowin