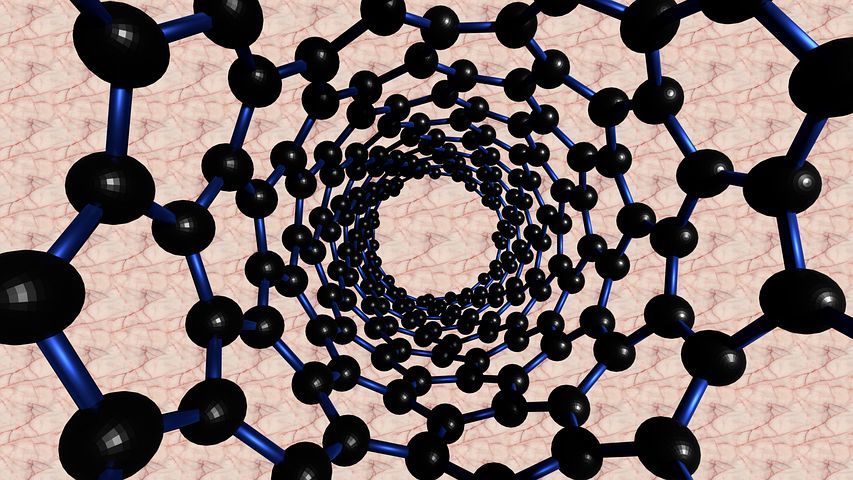

The use of carbon nanotubes, nanowires, and nanoparticles is often hailed as the manufacturing sector of the future, but critics still point to a lack of real-world applications for these cutting-edge raw materials.

This is despite the fact that carbon nanotubes are currently used in thousands of everyday products, from electronics to sports equipment to plastics. It is pure ignorance to believe that nanotechnology will not influence our lives; it already is.

And if more evidence were needed of how much nano-raw materials will further play a role in our lives, a team of mechanical engineers and material scientists from UCLA have developed a process which uses nanoparticles to strength the atomic structure of glass.

Given the growing market for toughened glass in cars, doors, and tables, for home and business security, as well as on tablet and mobile phone screens, the fact that a nanoparticle raw material can make glass that is five times harder to break than any glass currently available is sure to catch glass-manufacturers attention.

In fact, the glass is so tough it is predicted to be used in new architectural and design elements or for highly specialised industrial applications, such as engine components or tools that are required to withstand high temperatures.

The method for producing the tougher glass has now been published in the journal Advance Materials, where the team explain how previous attempts at applying nanomaterials in glass found problems with dissemination, stating that, “… the fracture toughness of traditional glasses is very low due to intrinsic brittleness, significantly limiting their use for structural applications. While nanoelements may be added into glasses and ceramics to form nanocomposites with enhanced properties, it is extremely difficult to distribute and disperse them inside the liquid glass/ceramic matrix with traditional processing methods.”

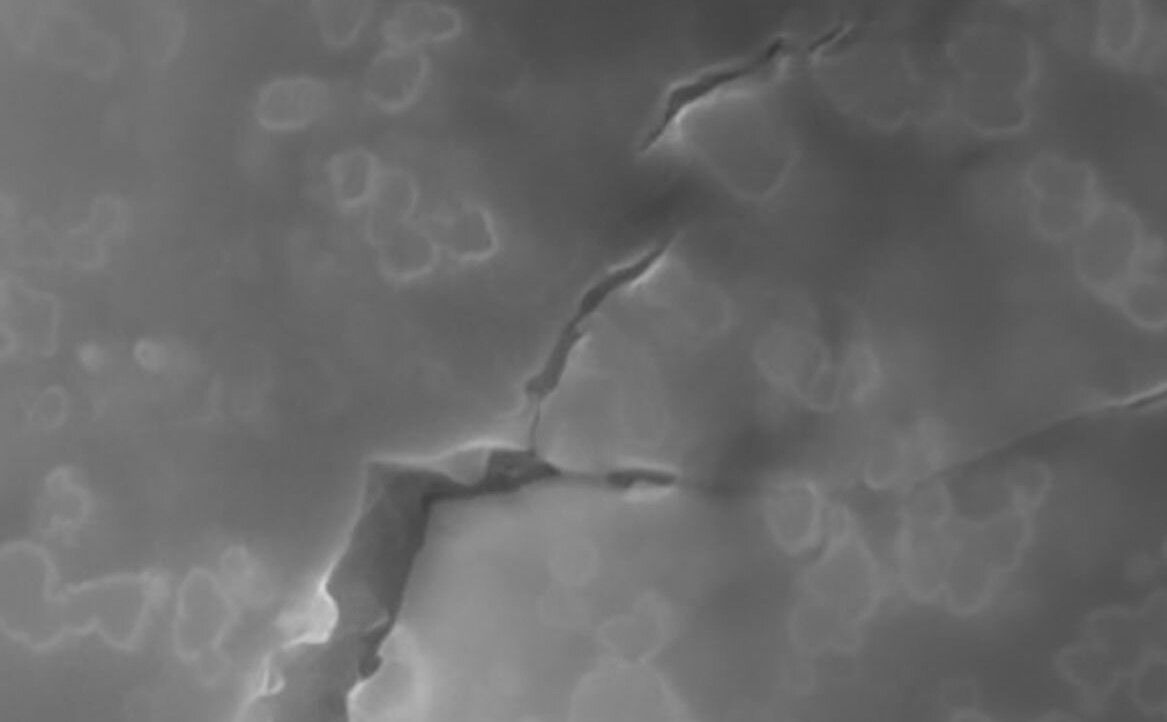

In material science, ‘toughness’ is measured by how much energy a material can absorb without fracturing. Ceramics and glass are very brittle, and so crack easily. Current measures to toughen them often involve adding chemical coatings or thin films. But these do little to change the material itself, merely providing a protective barrier.

To solve this problem, the researchers from the UCLA Samueli School of Engineering looked at how metals absorbed energy on an atomic level, as Prof. Xiaochun Li, the study's principal investigator, explains, “The chemical bonds that hold glass and ceramics together are pretty rigid, while the bonds in metals allow some flexibility. In glass and ceramics, when the impact is strong enough, a fracture will propagate quickly through the material in a mostly straight path. When something impacts a metal, its more deformable chemical bonds act as shock absorbers and its atoms move around while still holding the structure together.”

This thinking led the team to consider adding nanoparticles as a raw material to give the glass different properties. As the scientific journal Phys.org reports, “The researchers hypothesized that by infusing glass with nanoparticles of silicon carbide, a metal-like ceramic, the resulting material would be able to absorb more energy before it would fail. They added the nanoparticles into molten glass at 3,000 degrees Fahrenheit (1648 degrees Celsius), which helped ensure that the nanoparticles were evenly dispersed.”

Previous attempts at sintering powders or nanoparticles into molten glass under pressure had not allowed the mixture to spread evenly enough, creating areas of untoughened glass.

However, the new method allows the nanoparticles to distribute themselves uniformly throughout the mixture. Once the material has solidified, the nanoparticles act like ‘roadblocks’ against potential breakages.

This means, that when a fracture does occur, the nanoparticles cause it to splinter away into tiny branches, rather than taking a direct path. The result is a glass that can absorb a lot more energy and impact before it shatters.

While at present, the use of nanoparticles via this method gives the glass a milky, rather than clear, appearance, the team are confident that the process can be modified to produce clear glass.

Alternatively, the authors are looking to adapt their method so that nanoparticles could be applied to ceramics. These toughened ceramics could also find numerous applications throughout industry where a material is required to absorb high impact or extreme heat, perhaps even in space.

Photo credit: Xinology, Thanachai, Phys.org, Wheatonarts, & Youtube