The research team that brought us the non-stick ketchup bottle has now developed their ideas further to allow for even stickier substances to slide smoothly. While the previous discovery solved the problem of mayonnaise jars and shower gel bottles, this latest invention will have far more industrial applications that could save money and improve quality in the chemical, food, pharmaceutical industries, and beyond.

The idea has been advanced by Kripa Varanasi, a professor of mechanical engineering at MIT, who was also a leading researcher in the earlier ‘ketchup bottle’ coating.

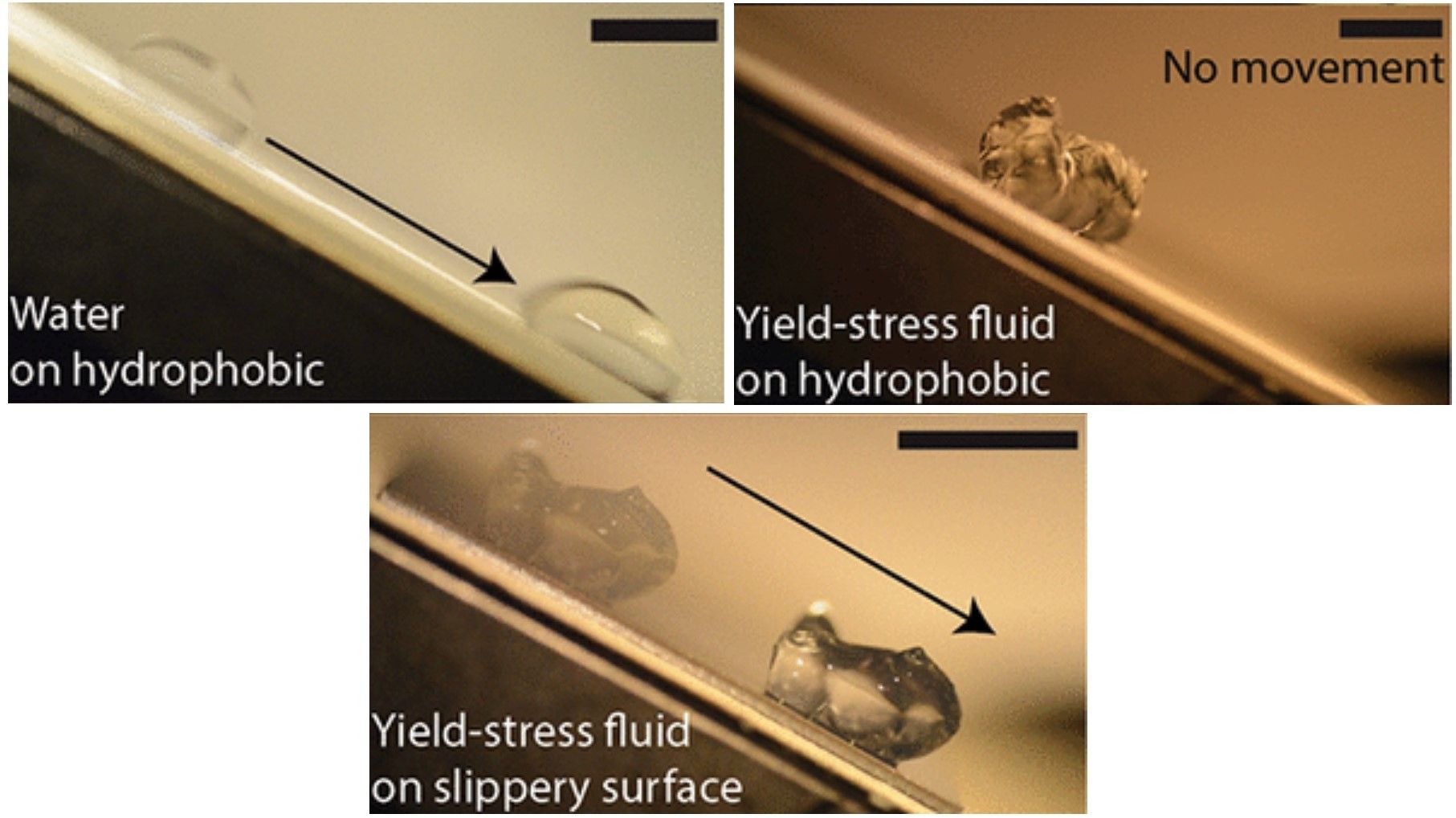

Now Varanasi, working with Leonid Rapoport PhD and Brian Solomon PhD, have focused on stickier, more solid materials, with a consistency similar to hair gel. Substances like this can be found all around us and are known to chemists as ‘yield-stress fluids’, because unlike oils and water they will not flow down a surface under their own weight. Even if a container is held upside down, they require mechanical pressure, either a push or a shake or a squeeze of a bottle, before they move. This not only costs energy but can also leave some of the substance still stuck to the side of the container.

The importance of overcoming the grip of yield-stress fluids was outlined by the team in the scientific journal Applied Materials and Interfaces, where they explain how, “A common problem which we encounter on a daily basis is dispensing of yield-stress fluids such as condiments, lotions, toothpaste, etc. from containers. Beyond consumer products, assuring the flow of yield-stress fluids such as crude oil, mud, blood, paint, pharmaceutical products, and others, is essential for the respective industries. Elimination of wall-induced friction can lead to significant savings in the energy required for flow of yield-stress fluids, as well as associated product loss and cleaning costs.”

While the ability to reduce such frictions may seem insignificant, it can make a difference. For example, in the baking industry, a machine scrapes dough out of containers so it can be placed into the oven. Not only does this scraping leave remnants behind, but the pressure applied impacts on the dough, destroying air bubbles and making for a denser, lower quality loaf. The new nanocoating would reduce waste and make better bread. As Varanasi states, “…beyond getting everything out of the container, you now add higher quality.”

In other industries, the difference may be even greater, as pressure applied to substances more delicate than dough can be very expensive.

For example, in the pharmaceutical industry, the use of scrapers or pushers to move gel-like drug materials through pipes and mixing tanks can damage the quality of active compounds and proteins, leave behind expensive residue, and lessen the effectiveness of medicines.

To avoid this damage and waste, the team analysed the way that yield-stress fluids react with surfaces. As Rapoport explains, “Generally speaking, surfaces are enablers. Superhydrophobic surfaces, for example, enable water to roll easily, but not all fluids can roll. Our surfaces enable fluids to move by whichever way is more preferable for them — be it rolling or sliding. In addition, we found that yield-stress fluids can move on our surfaces without shearing, essentially sliding like solid bodies. This is very important when you want to maintain the integrity of these materials when they are being processed.”

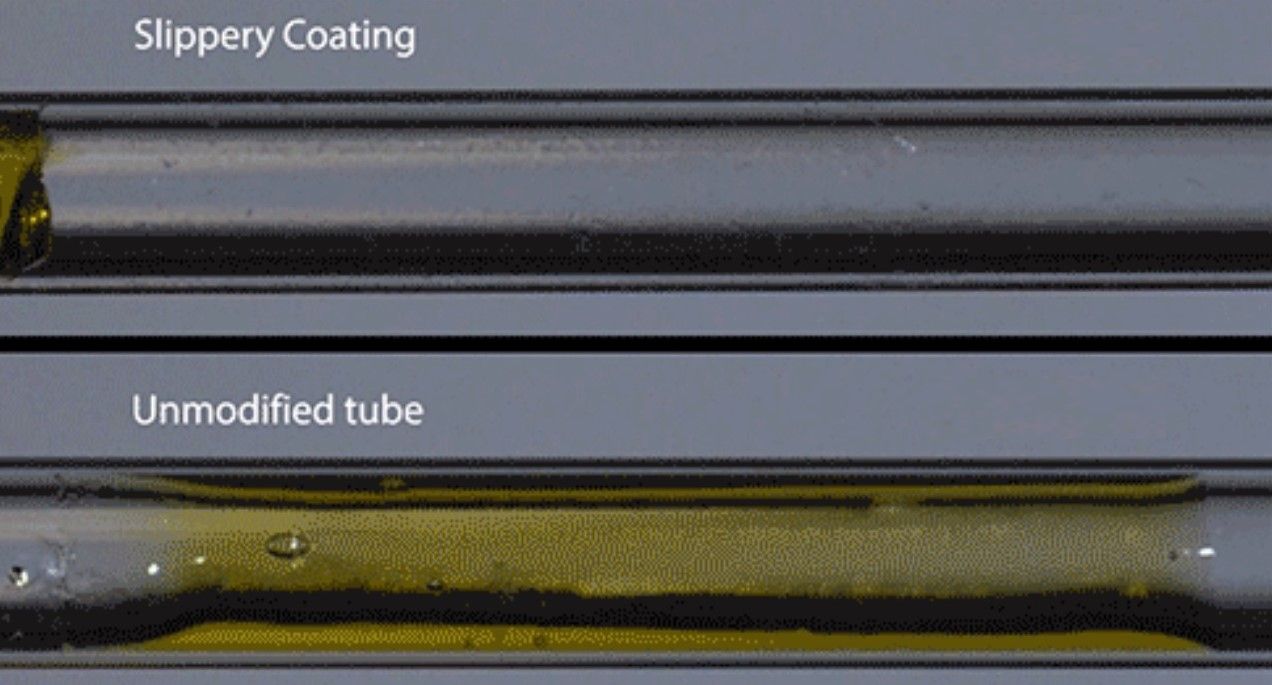

The MIT website describes how this was done as follows; “Like the earlier version of slippery surfaces Varanasi and his collaborators created, the new process begins by making a surface that is textured at the nanoscale, either by etching a series of closely spaced pillars or walls on the surface, or mechanically grinding grooves or pits. The resulting texture is designed to have such tiny features that capillary action — the same process that allows trees to draw water up to their highest branches through tiny openings beneath the bark — can act to hold a liquid, such as a lubricating oil, in place on the surface. As a result, any material inside a container with this kind of lining essentially only comes in contact with the lubricating liquid, and slides right off instead of sticking to the solid container wall.”

In fact, the researchers have made the new nanocoating so effective that they claim it can achieve almost 100 percent friction reduction for gel-like fluids; a state that Varanasi has labelled ‘infinite slip’.

While the commercial success of this new coating is not as clear as a ketchup bottle, it is evident that the scale and reach of nanocoating applications continues.

A short video showing a comparison of gel flow with and without the nanocoating can be viewed on the MIT website.

Photo credit: MIT, Videoblocks, & Applied Materials and Interfaces