Nanotechnology specialists have manufactured carbon nanotube films that can be used as antennas for wireless applications. Not only are the nanotubes stronger and more flexible than the currently used copper wires, but they are extremely lightweight, have a comparable rate of transmission, and can essentially be painted onto devices.

The discovery was made at Rice University's Brown School of Engineering by a research team who had already made nanotechnology breakthroughs in 2017 using nanotube fibres as antennas. This work proved ground-breaking for multiple applications in thin electronics, including heart surgery, brain implants, streamlined devices for aircraft and space vehicles, as well as wearable electronics, and health monitor bracelets.

As Rice graduate student Amram Bengio, the paper's lead author stated at the time, “Applications for this material are a big selling point, but from a scientific perspective, at these frequencies carbon nanotube macro-materials behave like a typical conductor.”

Adding that, “Antennas typically have a specific shape, and you have to design them very carefully.”

While it is technically possible for very thin copper wires to be used in place of the more common 30-gauge wires, they become very fragile and impractical for many uses. This led the team towards using carbon nanotubes as a raw material for manufacturing antennas.

As Matteo Pasquali, a Rice lab engineer who co-authored the study notes, “As you go to very thin antennas at high frequencies, you get less of a disadvantage compared with copper because copper becomes difficult to handle at thin gauges, whereas nanotubes, with their textile-like behavior, hold up pretty well.”

Previously, using carbon nanotubes (CNTs) as antennas was thought impossible due to physical limits, which kept them adhering to the ‘classical relationship between radiation efficiency and frequency’. But this latest breakthrough was borne from improvements made in ‘fluid phase CNT processing’, which lets the CNTs form with ‘better alignment and conductivity’.

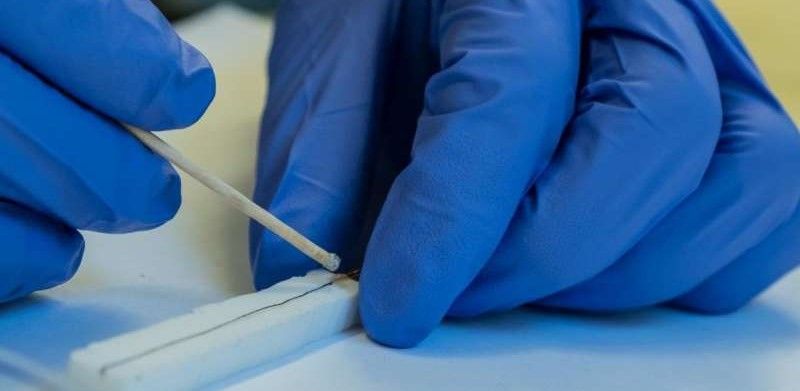

Specifically, the Rice University website outlines how the antennas are made as follows; “To make the films, the Rice lab dissolved nanotubes, most of them single-walled and up to 8 microns long, in an acid-based solution. When spread onto a surface, the shear force produced prompts the nanotubes to self-align.”

Adding that, “The test films were about the size of a glass slide, and between 1 and 7 microns thick. The nanotubes are held together by strongly attractive van der Waals forces, which gives the material mechanical properties far better than those of copper.”

The results are exceptionally robust yet very thin antennas, that at the target frequencies of 5, 10 and 14 gigahertz are able to easily hold their own with their metal counterparts.

As the results, now published in the journal Applied Physics Letters, show, “We measured a radiation efficiency of 94% at 10 GHz and 14 GHz, matching equivalent copper antennas. Furthermore, the minimum CNT film thickness required to match the performance of copper drops with increasing frequency due to reduced losses from the skin effect.”

Furthermore, the online journal Phys.org notes how much more practical the new method is, stating that, “… although gas-phase deposition is widely employed as a batch process for trace deposition of metals, the fluid-phase processing method lends itself to more scalable, continuous antenna manufacturing.”

The fact that the process is suitable for upscaling to an industrial level has left the team considering the many applications for such super thin, very lightweight, and sturdy antennas. Possibilities include use on unmanned aerial vehicles or in wireless telemetry portals for downhole oil and gas exploration. Additionally, because the new antennas are suitable for 5G networks, they could be placed on any device that needs to be connected to the ‘Internet of Things’.

iven the wide scope of products that this may include, Bengio has founded a company to further develop the idea and to bring carbon nanotube antennas to the market. Now working as CEO and founder of Wootz, Bengio states, “We were going up to frequencies that aren't even used in Wi-Fi and Bluetooth networks today but will be used in the upcoming 5G generation of antennas.”

“There are limits because of the physics of how an electromagnetic wave propagates through space. We're not changing anything in that regard,” observes Bengio. “What we are changing is the fact that the material from which all these antennas will be made is substantially lighter, stronger and more resistant to a wider variety of adverse environmental conditions than copper.”

Photo credit: RiceUniversity, ExpressVPN, & CIC