Nanotechnology specialists at MIT have made major breakthrough in electronics by constructing a microprocessor from carbon nanotube transistors. It is a discovery that will lead to greener, faster, and more powerful devices than those currently available with traditional silicon processors.

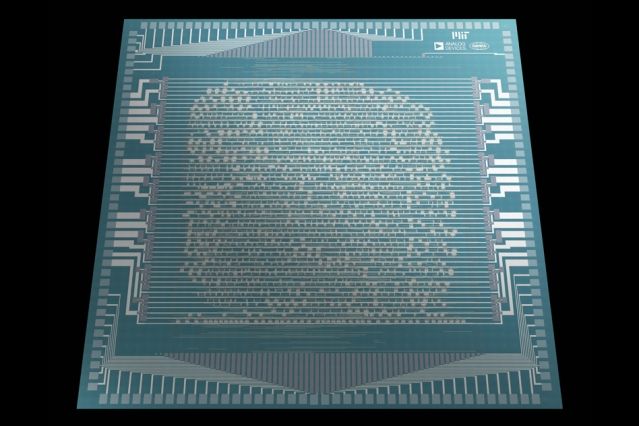

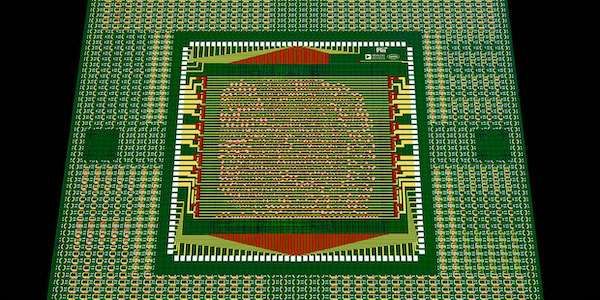

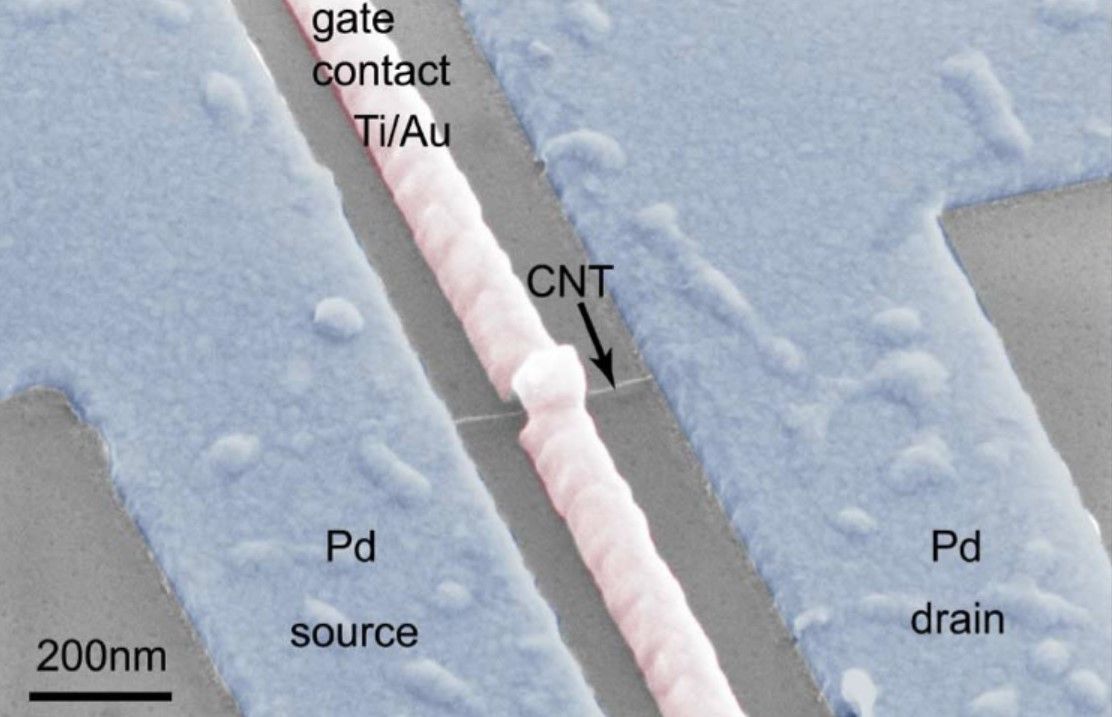

Title picture shows a microscopic image of a microprocessor built from carbon nanotube field-effect transistors.

At present, microprocessors are reaching their physical limits. While for decades, the technology industry has been squeezing more and more silicon transistors into ever smaller spaces, at some point this model will cease to work. Further increases in computational power will require something different to the 1950’s technology that is the silicon chip.

Constructing transistors with carbon nanotubes is seen the key to building next-generation computers, with research showing that carbon nanotube field-effect transistors (CNFET) will be able to operate at far greater speeds than silicon transistors yet will use 10 times less energy.

As the study’s co-author Max M. Shulaker, explains, “There are limits to silicon. If we want to continue to have gains in computing, carbon nanotubes represent one of the most promising ways to overcome those limits.”

The MIT team have now published their findings in the journal Nature, where they describe a, “16-bit microprocessor based on the RISC-V instruction set, [that] runs standard 32-bit instructions on 16-bit data and addresses, comprises more than 14,000 complementary metal–oxide–semiconductor CNFETs and is designed and fabricated using industry-standard design flows and processes.” Adding that the study represents, “… a promising path towards practical beyond-silicon electronic systems.”

The practicality of CNFETs has already been proven, with the microprocessor able to accurately execute numerous commands, including a variation of a classic when it printed, “Hello, World! I am RV16XNano, made from CNTs.”

“This is by far the most advanced chip made from any emerging nanotechnology, promising high-performance and energy-efficient computing,” says Shulaker. “[It] completely re-invents how we build chips with carbon nanotubes.”

With their excellent electrical conductivity, carbon nanotubes have long been seen as a potential replacement for silicon in transistors. However, getting there wasn’t easy, and it took decades of study to overcome the three main challenges involved; material defects, manufacturing defects, and functional issues.

Solving CNT Defects

CNFETs need semiconducting properties which can be switched on and off, to reflect the 1 and 0 bits. However, when synthesizing CNTs it is natural and unavoidable that some of the tubes will turn out to be metallic, slowing down or even stopping the switching completely. Intrinsic defects that Shulaker describes as ‘the bane of the field’.

To prevent these failures requires carbon nanotubes with 99.999999% purity, something that is practically impossible to produce today.

To solve this, the researchers created a method called DREAM (‘designing resiliency against metallic CNTs’), which “positions metallic CNFETs in a way that they won’t disrupt computing”. This eased the pressure on the purity requirement by about four orders of magnitude, so 10,000 times less purity was needed. This means that the carbon nanotubes must be only 99.99% pure. Something that is currently available on the carbon nanotube market.

As the MIT website describes, “Designing circuits basically requires a library of different logic gates attached to transistors that can be combined to, say, create adders and multipliers — like combining letters in the alphabet to create words. The researchers realized that the metallic carbon nanotubes impacted different pairings of these gates differently. A single metallic carbon nanotube in gate A, for instance, may break the connection between A and B. But several metallic carbon nanotubes in gates B may not impact any of its connections.

“In chip design, there are many ways to implement code onto a circuit. The researchers ran simulations to find all the different gate combinations that would be robust and wouldn’t be robust to any metallic carbon nanotubes. They then customized a chip-design program to automatically learn the combinations least likely to be affected by metallic carbon nanotubes. When designing a new chip, the program will only utilize the robust combinations and ignore the vulnerable combinations.”

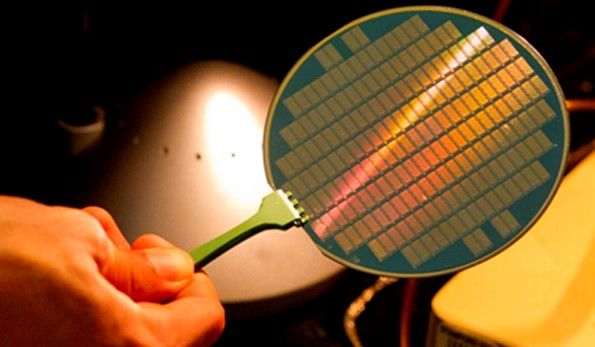

“The ‘DREAM’ pun is very much intended, because it’s the dream solution,” says Shulaker. “This allows us to buy carbon nanotubes off the shelf, drop them onto a wafer, and just build our circuit like normal, without doing anything else special.”

Solving CNT Microprocessor Manufacturing Problems

When CNFETs are made, carbon nanotubes in solution are deposited onto a wafer which has predesigned transistor architectures on it. However, inevitably, some carbon nanotubes randomly stick together in bundles, contaminating the chip.

To remove them the team devised a process called RINSE (‘removal of incubated nanotubes through selective exfoliation’).

This involved pre-treating the wafer with an agent that ‘promotes carbon nanotube adhesion’. Then, the wafer is coated with a special polymer and dipped in a solvent. This washes the polymer away, carrying the big bundles with it, while the single carbon nanotubes remain attached and in place. According to the researchers, this cleansing method, “leads to about a 250-times reduction in particle density on the chip compared to similar methods”.

Solving CNT Microprocessor Functionality

Binary computing works with two types of transistors: those which turn on with a 1 bit and off with a 0 bit (so called ‘N’ types), and those which do the opposite (‘P’ types).

Making these two types of transistors with carbon nanotubes often led to inconsistencies and varying performance levels. What was required was a way to ‘tune’ their function and optimization.

To this end, the team created a process called MIXED (metal interface engineering crossed with electrostatic doping).

As the MIT website explains, “In this technique, they attach certain metals to each transistor - platinum or titanium - which allows them to fix that transistor as P or N. Then, they coat the CNFETs in an oxide compound through atomic-layer deposition, which allows them to tune the transistors’ characteristics for specific applications. Servers, for instance, often require transistors that act very fast but use up energy and power. Wearables and medical implants, on the other hand, may use slower, low-power transistors.”

By solving these three challenges, the team has created the world’s first 16-bit processor with 14,000 CNFETs. A huge scientific advance from the previous work by the same team six years ago, which created a microprocessor containing only 178 CNFETs and operated on only one bit of data.

Such progress may even mean that it is time to start Moore’s Law anew and begin calculating the doubling of computer power every two years with carbon nanotube microchips.

Certainly, the publication of this study will allow others in the technology and nanotechnology industries to work towards ever more powerful machines. Especially since the MIT team have already begun realizing the manufacturing techniques in a transistor factory, funded by the Defense Advanced Research Projects Agency, which also supported the research. And while no one can predict exactly when silicon will be replaced by carbon nanotubes, Shulaker believes that microprocessors made entirely from CNTs could be on sale in less than five years. As he says, “We no longer think it’s a question of if, but when.”

Photo credit: MIT, Circuitcellar, StanfordUniversity, Amazon, Engineering, Phys.org, VTM, & Tomshardware