A scientist from Delaware University in America is attracting a great deal of attention for the novel way he has been able to manufacture carbon nanotubes and graphene frameworks. In fact, his latest achievement, the 3-D printing of pure carbon nanotube structures, is believed to be a world first and may open up a whole new field in carbon nanotube applications.

Kun (Kelvin) Fu, an assistant professor of mechanical engineering, had already impressed the nanotechnology community with his work on nanotube semiconductors, as well as his cooperation in breakthrough research on the manufacture of graphene nanosheets designs through nano-holes.

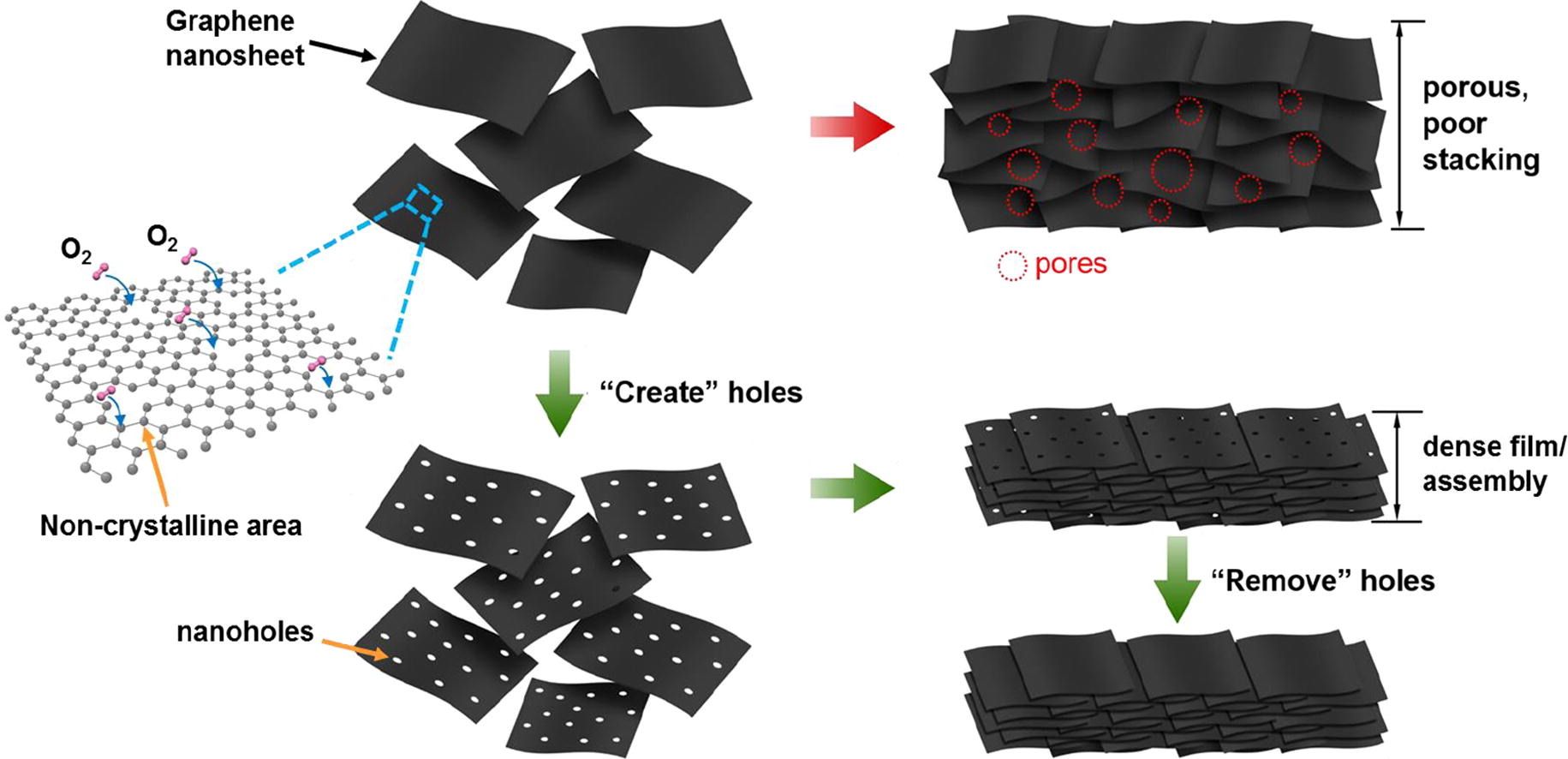

This work revolved around the challenge of making structures from layered graphene, as this often causes gas or liquids to become trapped between individual sheets. To solve this problem, nano-holes with a diameter of approximately 15 nm were made in the graphene sheet, to create so-called ‘holey graphene’. These holes allow for the removal of gases or liquids. However, once complete a process was needed to fix the holes to enable the construction of the layered structures.

As the journal Materials Today, reported at the time, Fu and his colleagues devised a, “… high-temperature process to effectively repair the nano-holes and recover the high-quality graphene conjugated network.”

The result was the manufacture of, “… dense graphene articles that exhibited an ultrahigh conductivity … and superior thermal conductivity … enabling the facile and scalable fabrication of high-quality graphene constructs, which can be easily integrated into the next generation of electronic circuits and high-power battery systems for highly efficient and lightweight thermal management.”

Now Fu has built on this understanding of graphene and nanoscale objects, by using a 3-D printer to make pure carbon nanotube architectures. All previous research had been unable to achieve this feat. As the University of Delaware website notes, “It is difficult to make high-density carbon nanotube inks concentrated enough to flow through a 3-D printer and form 3-D structures, but Fu developed a novel and completely different technique. Using a unique 3-D printing technique developed recently in Fu's lab, Fu printed a variety of complex CNT 3-D structures, including tiny replicas of the Eiffel Tower and the Great Wall of China, a small pig's face, a honeycomb, and a University of Delaware logo. Each one measures just a few centimetres wide is strong but lightweight.”

So lightweight, in fact, that, “The structures can sit on top of a dandelion that has gone to seed without crushing the fragile white seeds.”

Fu has yet to publish his findings but intends to explain the process in more detail at the upcoming IMECE International Mechanical Engineering Congress & Exposition being held in Salt Lake City in November, where there is expected to be significant interest in the novel approach that Fu has taken.

As Suresh Advani, the George W. Laird Professor of Mechanical Engineering and an associate director of the University of Delaware's renowned Center for Composite Materials observes, “This is quite an exciting discovery as it opens up applications in developing miniature and intricate sensors, serving as complex catalyst supports and also in biomedical applications where the focus will be to grow cells or use them as 3-D designed scaffolds.”

It is also thought that Fu’s development of such strong, lightweight, highly porous CNT structures using just a 3-D printer could also find useful applications in the production of composites, as carbon nanotubes can add great strength to polymer composites. Alternatively, they can be employed for their chemical stability or electrically conductivity to provide new possibilities in the design of batteries or electrical equipment, even at the nanoscale.

Tissue-engineered medical implants, water purification, and desalination processes provide other opportunities for the application of nanotechnologies.

“We can print a series of 3-D complex structures using carbon nanotubes. This is a pure CNT structure and no binder or polymer is needed,” explains Fu. Adding that, “According to literature, no one can do this.”

Photo credit: Phys.org, Techbriefs, & Cheaptubes