The mass production and handling of carbon nanotubes just became a lot easier, as a team of researchers has discovered an additive that alters their consistency into a manageable paste or polymer.

While bulk manufacturing of carbon nanotubes (CNTs) has long been possible, one of the trickiest problems for industrial producers of CNTs has been how to handle and transport tons of lightweight and fluffy tubes.

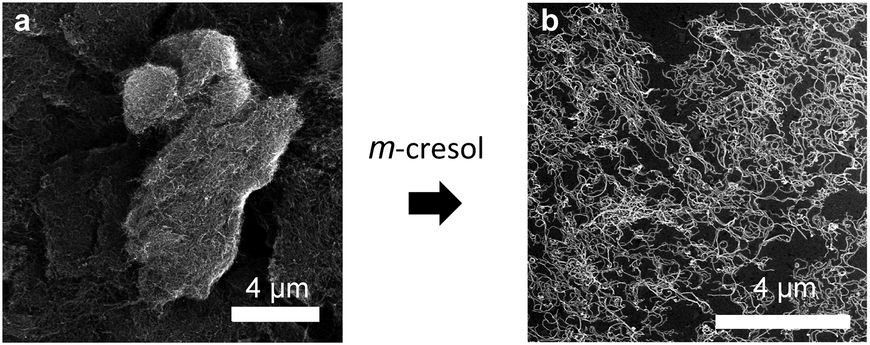

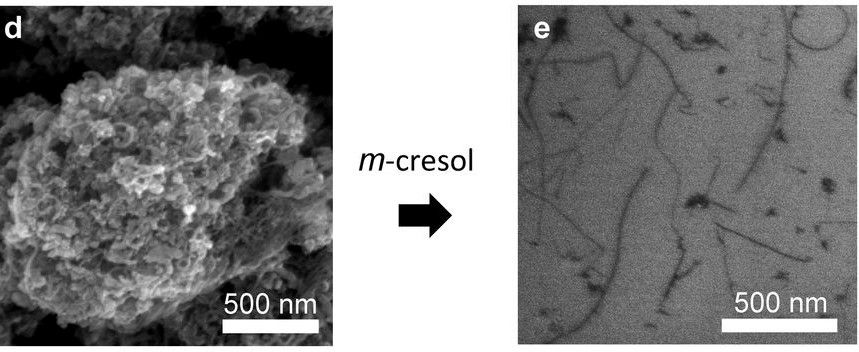

Previous efforts to get CNTs to adhere together have been unsuccessful. They involved adding chemicals which to create a nanotube powder, but this usually created clumps of tubes which were all twisted together. Other methods left a chemical residue that lessened the properties of the carbon nanotubes, or the tubes became chemically damaged.

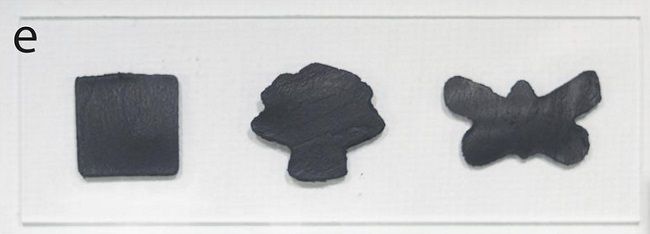

By using a common chemical once used in household cleaners, a team from Northwestern University in America have found a way to make carbon nanotubes stick together into a paste or dough-like substance. Not only does this make them easier to handle and transport, but the nanotubes gain the advantage of being malleable, so they can be worked like a polymer.

As Colm Gorey, the editor of the industry journal Silicon Republic, reports, “By using a solvent, called cresol, the team was able to make disperse carbon nanotubes at unprecedentedly high concentrations without the need for additives or harsh chemical reactions to modify the nanotubes.”

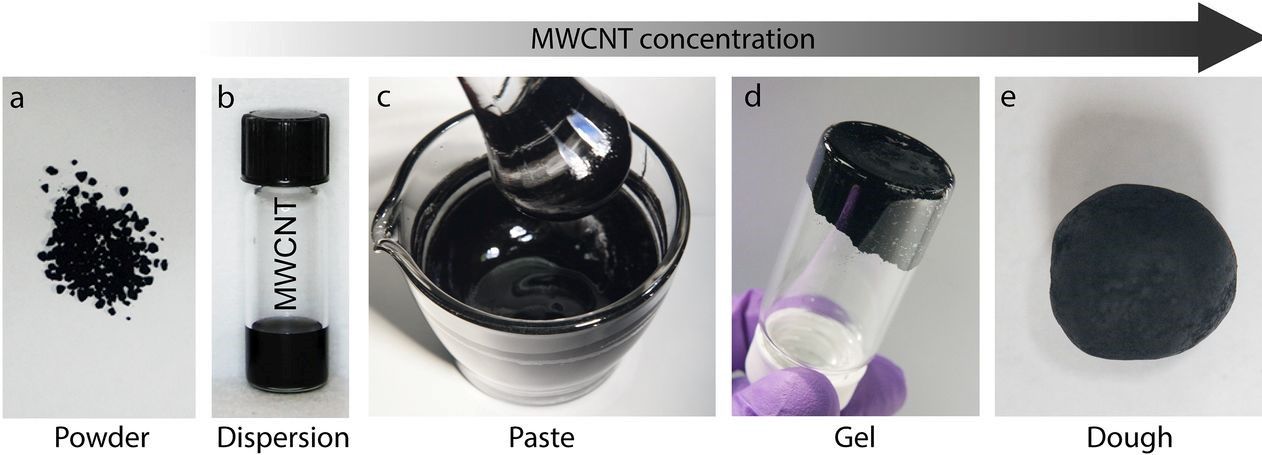

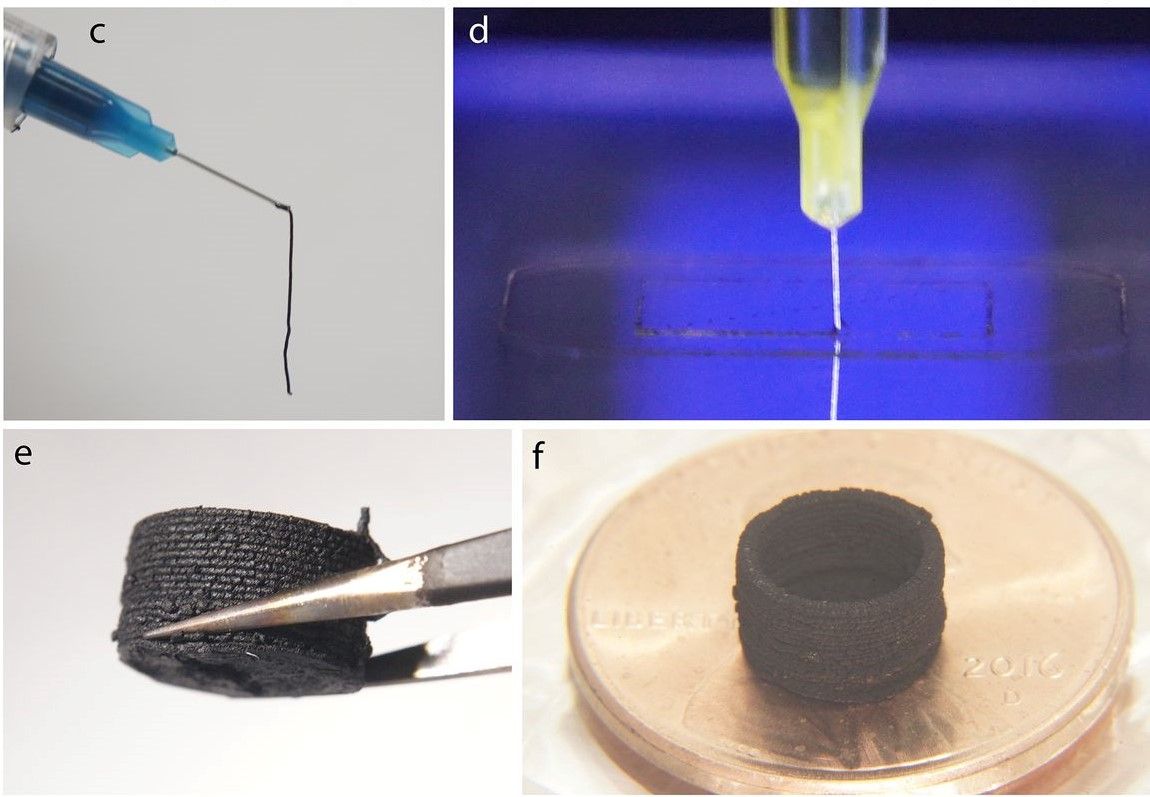

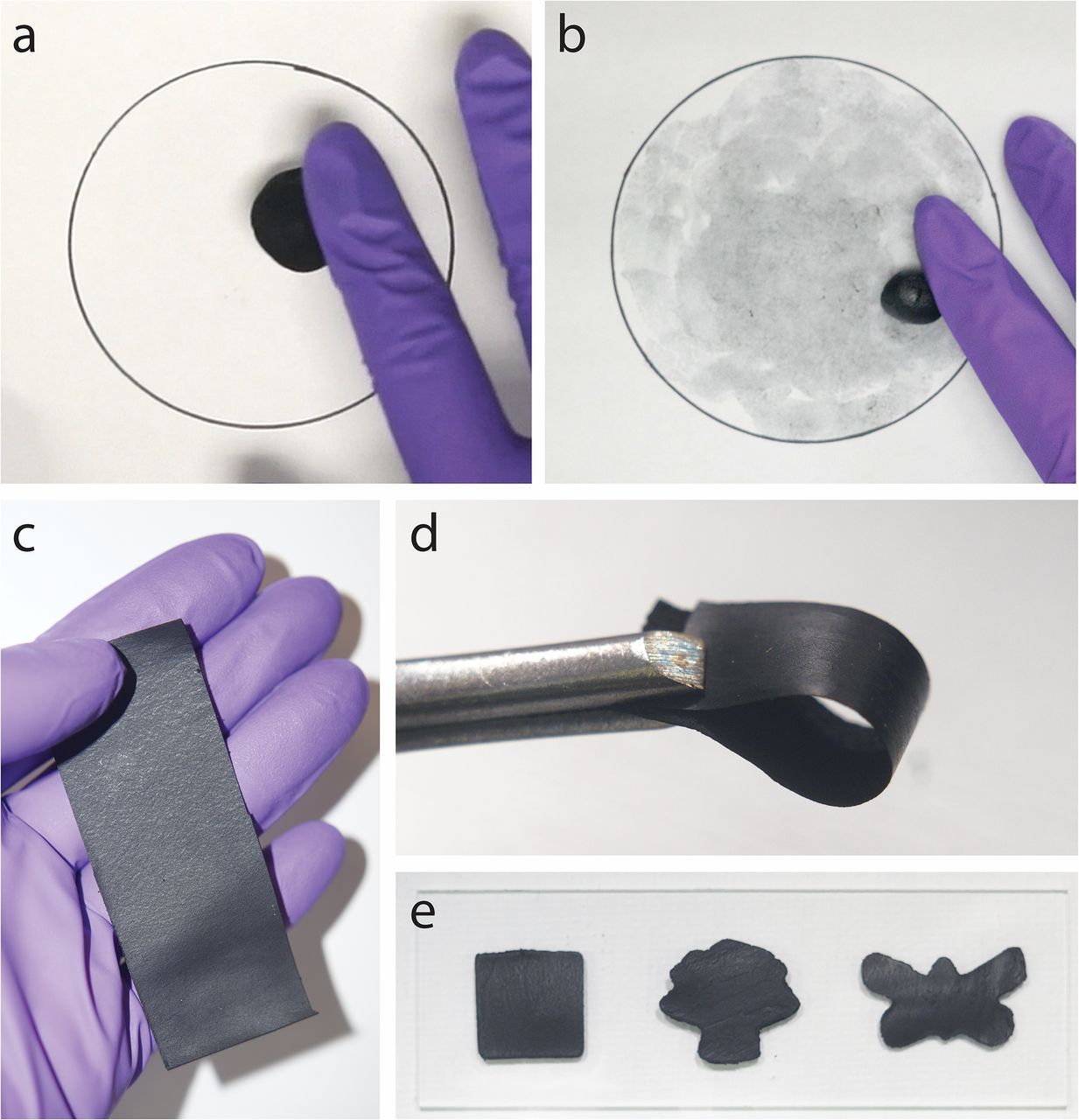

Further experiments showed that as the concentration of CNTs increased, the consistency of bulk CNT material changed. First from a dilute film on a liquid surface to a paste, then to a free-standing gel, and finally into a kneadable dough that could be shaped and formed by hand.

“Essentially, this solvent system now makes nanotubes behave just like polymers,” notes Jiaxing Huang, the study’s lead author.

The team have now published their results in the journal Proceedings of the National Academy of Sciences, where they state that, “… m-cresol and its liquid mixtures with other isomers, … can disperse carbon nanotube powders of many types at unprecedentedly high concentrations, rendering them polymer-like rheological and viscoelastic properties, and high processability. This makes carbon nanotube powders immediately usable by current materials-processing techniques for creating desirable structures or composites.”

Observing that, “Both Single-Walled Carbon Nanotubes (SWCNTs) and Multi-Walled Carbon Nanotubes (MWCNTs) can disperse at higher concentrations in m-cresol than in other common solvents such as N-Methyl-2-Pyrrolidone (NMP) and dimethylformamide (DMF).”

Furthermore, the addition of m-cresol was found to aid untangling while leaving a pure film of the tubes.

When the density of MWCNTs was increased to a maximum of 40 mg/mL, a thin paste was formed. Much like house paint, the paste had relatively high viscosity, making it suitable for applying with a brush.

Above the 40 mg/mL a freestanding gel was formed, with a consistency similar to toothpaste.

Finally, when the MWCNTs were added to the m-cresol at a ratio greater than 100 mg/mL a dough-like substance was produced. The substance that could be pressed or rolled without fracturing, and when kneaded onto paper, the dough left no stain (in contrast to the gel).

As the study explains, “This is due to the strong attraction between the nanotubes in the densely woven 3D network, which prevents them from leaving residues on paper. Control experiments were also done with other solvents, such as NMP, at similar concentrations. However, the resulting mixtures were too fragile to manipulate and broke into pieces upon kneading. Since the nanotube/m-cresol dough was kneadable and stain-free it must be highly cohesive and free of mechanically weak boundaries between segregated grains of CNTs.”

Carbon nanotubes have long been hailed as a revolutionary material that will change everything, but while CNTs are being used a raw material in the manufacture of thousands of everyday objects, their use has always been limited by the challenges of mass-production and the problems of applying a powder into modern production processes.

Amazingly, such an intricate and high-tech material like carbon nanotubes can be improved with such a simple chemical. Cresols are relatively inexpensive, stable at room temperature and ambient atmosphere, and are already produced in bulk form for multiple industries.

Additionally, by making mixing CNTs with m-cresol, the team from Northwestern University may have cleared the way for more widespread use of nanotubes. Being able to apply the tubes in varying densities as either a paste, gel, film, or dough will greatly aid mixing them with other modern composites. It will also allow their application by brush or in a more solid form. It will prevent waste from fluffy CNTs floating away and ultimately simplify CNT mass production.

As the study makes clear, “Cresol-based CNT dispersions exhibit polymer-like rheological and viscoelastic properties, rendering them polymer-like processability. It should help to overcome many aspects of the processability problems of CNTs, which has been one of the greatest hurdles preventing their widespread industrial application.”

Adding that, “The surprise that solvents with such simple molecular structures work so well is also likely to inspire many more discoveries about the interactions between organic molecules and graphitic surface, as well as in new material and engineering technologies based on CNTs and other graphitic nanostructures.”

As Jiaxing says, “It is really exciting to see cresol-based solvents make once hard-to-process carbon nanotubes as usable as common plastics.”

Photo credit: JiaxingHuangGroup, PNAS, & DatangChem